How DS Rubber Built a Zero-Leak 0.20 mm LPG/CNG Regulator Diaphragm for 3-Wheeler Gas Kits

DS Rubber engineered an ultra-thin LPG/CNG regulator diaphragm used in gas kits for 3-wheeler autorickshaws. The component is supplied to a Tier-1 gas kit manufacturer, supporting regulator assemblies integrated into vehicles produced by major Indian and global OEMs. Because the diaphragm directly governs pressure regulation and gas sealing, the application demanded extremely high consistency and zero-leak reliability in real-world operating conditions.

Client:

Category:

Date:

Location:

India

The Challenge

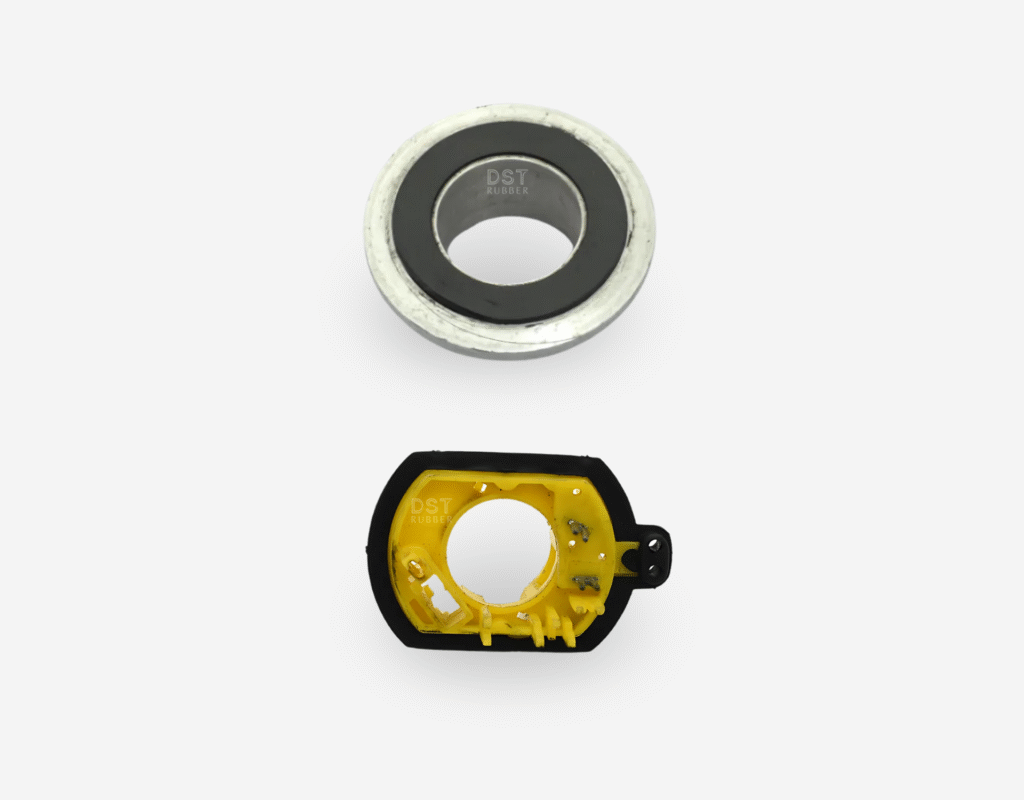

The core challenge was manufacturing a 0.20 mm total thickness diaphragm that could survive continuous cyclic pressure operation without loss of flexibility or sealing integrity. The design required a multi-layer construction comprising:

- 0.10 mm rubber layer

- 0.10 mm fabric reinforcement

- CAF gasket layer

At this thickness, even small deviations could cause fabric folding, wrinkling, thickness variation, or delamination between layers. In parallel, the diaphragm had to maintain stable performance under constant exposure to LPG, CNG, and n-Pentane, while also delivering ozone resistance and long service life in a safety-critical gas system.

The Engineering Response

DS Rubber approached the project as an engineering validation exercise rather than a standard production part. To accurately assess long-term fuel compatibility, the team invested in in-house immersion swell testing, enabling direct evaluation of compound behaviour in LPG, CNG, and n-Pentane environments.

Multiple custom rubber formulations were developed through controlled trials in collaboration with raw material manufacturers. The compounds were optimised to balance chemical resistance, flexibility, adhesion strength between dissimilar materials, and environmental durability. In parallel, moulds and process parameters were engineered to eliminate thin-part failure modes, ensuring uniform thickness and stable bonding across rubber, fabric, and CAF layers.

Process Control and Quality Assurance

To make the diaphragm production-ready at scale, DS Rubber implemented strict process and inspection controls. Precision tooling and controlled lamination ensured consistent 0.20 mm thickness and reliable multi-material bonding. Given the safety-critical nature of the application, 100% in-house leak testing was carried out on every diaphragm, supported by continuous monitoring to maintain repeatability across high-volume production.

The Impact

The engineered solution delivered long-term, field-proven performance. DS Rubber became the single supplier capable of meeting the Tier-1 customer’s BS-4 specification, and the program has remained active for over 25 years of uninterrupted supply.

Key outcomes include:

- Millions of diaphragms supplied with zero reported field failures

- Proven reliability across Indian and international operating conditions

- Continued support for BS-4 spare parts and development alignment for BS-6 requirements

Value Delivered

By combining material science, in-house testing, and process discipline, DS Rubber reduced supplier risk for the Tier-1 customer while enabling OEM compliance with evolving emission and safety norms. The project reinforced DS Rubber’s role as a long-term engineering partner capable of delivering ultra-thin, multi-material, safety-critical diaphragm solutions at scale.