How DS Rubber Enabled Reverse Engineering and Indigenization of AdBlue Engine Rubber Components

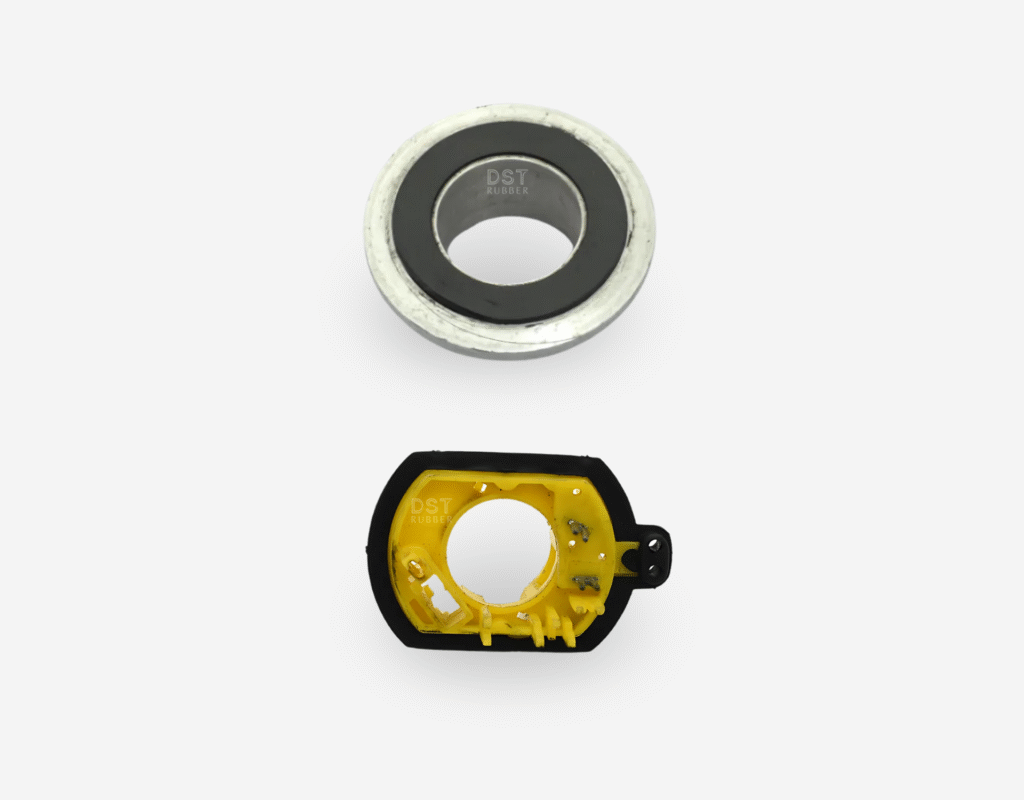

DS Rubber partnered with an automotive engine manufacturer developing an indigenised AdBlue (SCR) engine platform. The objective was to localise a set of rubber components that were previously imported, eliminating external dependency while maintaining OEM-grade performance. The scope included 13 critical rubber components used across the AdBlue dosing and flow control system, all of which needed to function together as a single, calibrated system.

Client:

Category:

Date:

Location:

India

The Challenge

The project began with zero starting data. There were no drawings, no material specifications, and no compound formulation details available for reference. While the customer’s engineering team had strong expertise in metal components, elastomer design and testing knowledge was limited, increasing development risk.

Adding to the complexity, most components were very small in size, making conventional rubber testing methods impractical. Reverse engineering required multiple tooling and process iterations, and some critical compound ingredients required for AdBlue compatibility were not available locally in India. Despite these constraints, the system had to deliver precise AdBlue flow rates and dosing accuracy to meet emission compliance requirements.

The Engineering Response

DS Rubber approached the project with a structured reverse engineering and indigenisation roadmap. This included material identification, property benchmarking, prototype validation, and iterative tooling development. Early in the program, DS Rubber also worked closely with the customer’s team to explain rubber-specific design sensitivities, testing limitations, and performance trade-offs.

Material identification began with in-house burn tests to classify elastomer families, followed by FTIR analysis to accurately identify base polymers. These findings were benchmarked against application requirements such as AdBlue compatibility, flexibility, and long-term durability. Based on this data, DS Rubber defined target material behaviour rather than relying on incomplete reverse references.

Freezing mechanical and physical properties presented a unique challenge because standard test slabs or buttons could not be produced due to the miniature size of the components. To overcome this, DS Rubber designed special fixtures and custom test methods that allowed properties such as hardness (Shore A), compression set, tensile strength, and elongation to be derived directly from finished parts. These results were then correlated with standard test data to establish reliable specifications.

Tooling, Process, and Material Strategy

Custom moulds were developed for all 13 components, with multiple design iterations carried out to fine-tune dimensional stability, functional performance, and assembly fitment. A continuous feedback loop between testing outcomes and tooling modifications ensured steady convergence toward production-ready designs.

Where performance-critical compound ingredients were unavailable locally, DS Rubber made the decision to import specific raw materials rather than compromise on durability or system behaviour. This approach balanced localisation goals with the functional reliability expected in an OEM engine platform.

The Impact

All 13 rubber components were successfully developed, validated, and integrated as a functional system. The components worked together to deliver the intended AdBlue flow rate and dosing behaviour, enabling the customer to indigenise a complex rubber-intensive subsystem without sacrificing performance.

The project reduced dependency on imported components, lowered long-term supply risk, and positioned the customer for faster deployment of an AdBlue-compliant engine platform. It also established DS Rubber as a trusted engineering and development partner, not just a manufacturing vendor.

Value Delivered

DS Rubber transformed a no-data reverse engineering challenge into a production-ready rubber system. The engagement provided critical elastomer engineering expertise to a predominantly metal-focused OEM team, reduced development risk through structured testing and iteration, and supported faster time-to-market for emission-compliant engine programs.