Rubber-Plastic Bonded Parts

Reliable Rubber-Plastic Bonded Parts for Critical Industrial Systems

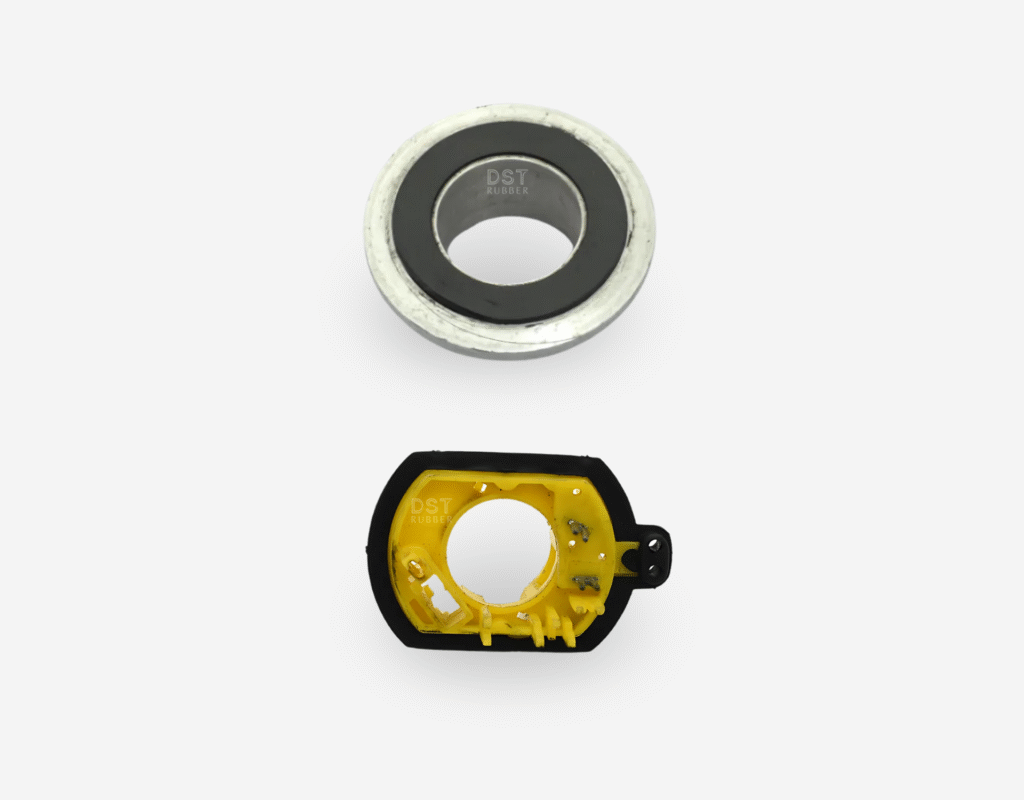

At DS Techno Rubber, we manufacture high-performance rubber-plastic bonded parts tailored for modern engineering needs across industries. These components combine the flexibility and sealing efficiency of rubber with the lightweight strength of engineered plastics. Ideal for applications requiring electrical insulation, vibration damping, and precision sealing, our rubber-plastic bonded parts serve automotive, electronics, and consumer sectors with consistent quality and long-term durability.

Performs Reliably in Extreme Temperatures

Reduces Vibration and Mechanical Wear

Ensures Uniform and Durable Bonding

What are Rubber-Plastic Bonded Parts?

Rubber-plastic bonded parts are components formed by bonding rubber to plastic substrates, combining the flexibility and sealing performance of rubber with the lightweight, rigid characteristics of plastic. These parts are engineered for use in dynamic environments requiring vibration damping, insulation, and dimensional stability. The rubber layer absorbs mechanical shock and isolates vibrations, while the plastic base provides structural integrity and design flexibility. A strong and uniform bond between the materials is essential to prevent delamination, stress failure, or leakage during operation, ensuring long-lasting functionality and performance.

DS Techno Rubber manufactures high-quality rubber-plastic bonded parts tailored to specific application needs across sectors. Our bonding process ensures optimal adhesion, temperature resistance, and reliability even under high mechanical or environmental stress.

Application Areas of Rubber-Plastic Bonded Parts

Vibration Isolation & Damping

Designed to absorb mechanical shocks and reduce vibration in automotive, appliance, and machinery components, improving durability and end-user comfort.

Sealing Efficiency

Rubber-plastic parts offer airtight and watertight seals in fluid systems, valves, and precision enclosures. Ideal for both industrial and medical applications where leak prevention is critical.

Electrical Insulation & Safety

Used in electronic connectors and housings, these bonded parts provide insulation that prevents short circuits and ensures safety in high-voltage environments.

Lightweight Structural Integration

Combining plastic strength and rubber flexibility, these parts create lightweight assemblies with strong performance in automotive and consumer products.

Our Range of Rubber-Plastic Bonded Parts

We offer a wide variety of metal-rubber bonded parts designed to meet the specific needs of various industries.

Our metal-rubber bonded parts are designed for optimal performance in both automotive and industrial applications, where precision and durability are paramount. Whether you’re looking for vibration-damping components, fluid control parts, or structural support solutions, we have the expertise and product range to meet your needs.

Overmolded Bonded

Parts

These parts offer seamless integration and uniform bonding, combining rubber and plastic into a single functional unit. They ensure excellent sealing, long-term durability, and dimensional stability in components exposed to vibration, stress, environmental changes & mechanical wear.

Adhesive Bonded Components

These components rely on chemical adhesion for a strong, reliable bond between materials. Suitable for complex designs and mixed-material requirements, they offer flexibility in design and are widely used where controlled bonding strength is critical to product life.

Mechanically Interlocked Designs

Designed with precision grooves or locking features, these parts deliver high resistance to delamination and mechanical failure. The interlocking design enhances retention and ensures consistent performance in assemblies exposed to repeated motion, vibration, or load variations.

What Sets Us Apart

Comprehensive In-House Testing

Custom Compound Formulation

Robust Vibration Damping

Precise Testing Fixtures

Optimal Fluid Flow for Pumps

Long Shelf Life & Durability

Technical Importance of Rubber-Plastic Bonded Parts

Robust Bonding

Optimal Compatibility

Performance Under Extreme Conditions

These parts are designed to endure high temperatures and cyclic stresses, ensuring consistent performance and reliability in extreme environments.

Vibration Isolation & Damping

Durability & Longevity

Precision Engineering

Get Custom Rubber-Plastic Bonded Parts Tailored to Your Needs

FAQ

Plastic-rubber bonded parts are widely used in automotive, electrical, consumer goods, medical devices, and industrial equipment. They are applied in sealing systems, vibration control, protective housings, and precision components where flexibility, lightweight design, and durability are required.

These components combine the benefits of two materials to deliver:

- Lightweight yet strong performance

- High resistance to wear and environmental stress

- Reliable sealing and flexibility in complex assemblies

- Cost-effective production with customizable designs

- Versatility across multiple industries and operating conditions

Typical materials include:

Rubber: EPDM, NBR, Silicone, and Fluorocarbon (FKM) for sealing, flexibility, and environmental resistance.

Plastic: Nylon, Polypropylene, ABS, and PEEK for strength, chemical resistance, and dimensional stability.

They are produced using advanced moulding techniques where rubber is chemically or mechanically bonded to plastic substrates. This ensures a secure connection, enabling the part to withstand pressure, temperature fluctuations, and exposure to chemicals in critical applications.

When selecting, key considerations include:

- Mechanical strength and load requirements

- Exposure to chemicals, fluids, and temperature variations

- Bonding compatibility between plastic and rubber materials

- Shape, size, and design complexity for the application

- Compliance with industry-specific quality standards and certifications

Get a Custom Quote

Looking for high-quality custom rubber components? We’re here to provide you with tailored solutions that meet your exact requirements. Simply fill out the form below, and we’ll provide a personalized quote based on your specifications.