Fabric Positioning in Reinforced Diaphragms

Fabric positioning is essential in reinforced diaphragms, influencing durability, flexibility, and performance. Proper placement ensures the diaphragm can withstand stress and pressure fluctuations without wear or failure.

Fabric embedded within rubber enhances mechanical strength while maintaining flexibility. For high-pressure environments, the fabric needs more rigidity, while dynamic applications require increased elasticity. Misaligned fabric can cause uneven stress, leading to failure.

At DS Techno Rubber, we specialize in precise fabric positioning, customizing diaphragms for performance and durability across industries, including automotive and industrial machinery.

Diaphragm with Fabric Positioned at the Center

Positioning fabric at the center of a diaphragm enhances strength, flexibility, and pressure resistance, ensuring efficient performance across various applications. The central reinforcement allows the diaphragm to handle higher pressures without losing elasticity.

This fabric placement prevents overstretching and tearing, particularly in high-pressure environments. It also offers better control of movement, ensuring precise fluid or gas handling. The design boosts durability, making it ideal for pumps, valves, and actuators while maintaining structural integrity over time.

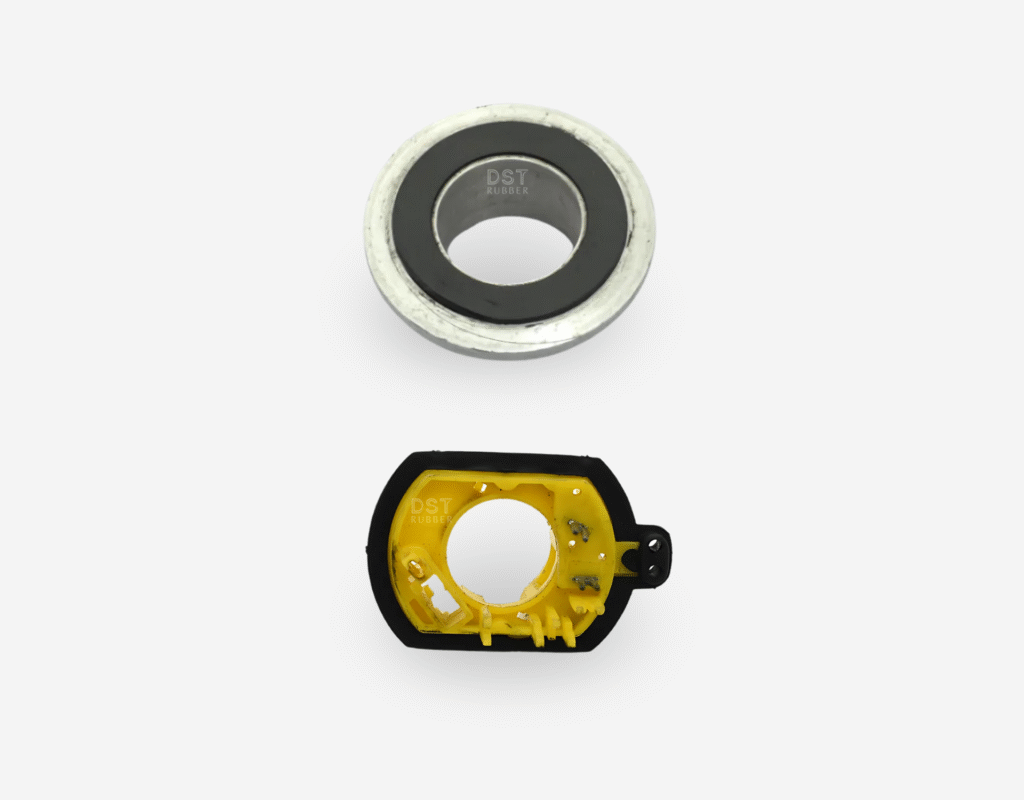

Diaphragm with fabric positioned on the outer side

Placing fabric on the outer side of a diaphragm enhances strength and durability, especially in high-stress areas. This reinforcement prevents deformation, tearing, and failure, particularly in high-pressure environments.

The outer fabric layer also protects against abrasion, temperature fluctuations, and chemicals, while improving sealing performance. This design maintains flexibility in the diaphragm’s center, allowing smooth movement, making it ideal for pumps, valves, and industrial machinery.

Proud Partnerships with Industry Leaders

DS Techno Rubber

35

Experience

iatf 16949 certified

DST is a trusted manufacturer with over 35 years of expertise in producing technically complex rubber components. IATF 16949 certified and recognized for excellence, we specialize in innovative solutions, ensuring top-quality products for automotive and non-automotive sectors.

With a strong focus on research and development, quality control, and customer satisfaction, we proudly serve clients across India, the USA, and Germany.