Advanced Performance Through Structural Reinforcement

At DST Rubber, we specialize in manufacturing reinforced rubber diaphragms that combine the flexibility of elastomers with the strength of embedded fabric or metal layers. These precision-engineered components are developed in India to deliver enhanced pressure stability, fatigue resistance, and long-term durability in mission-critical applications. With over 35 years of experience, we support industries such as automotive, fluid control, and industrial equipment with solutions built for consistency and demanding environments.

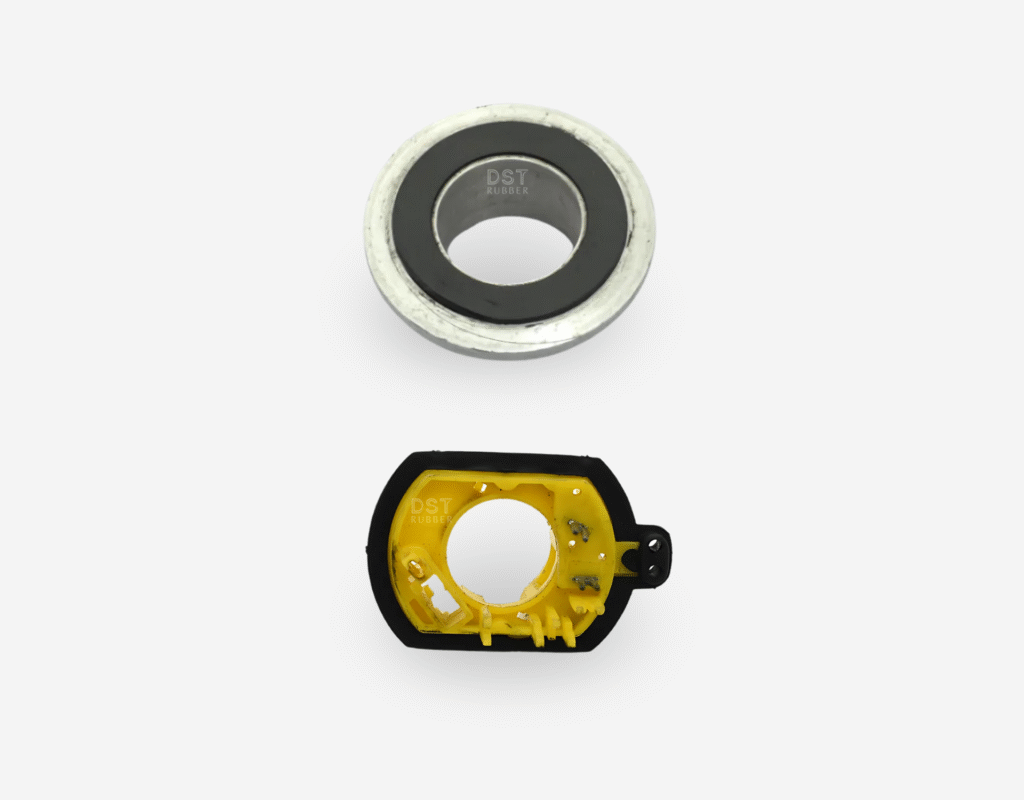

Fabric Reinforced Rubber Diaphragms

Metal Reinforced Rubber Diaphragms

Proud Partnerships with Industry Leaders

DS Techno Rubber

35

Experience

iatf 16949 certified

DST is a trusted manufacturer with over 35 years of expertise in producing technically complex rubber components. IATF 16949 certified and recognized for excellence, we specialize in innovative solutions, ensuring top-quality products for automotive and non-automotive sectors.

With a strong focus on research and development, quality control, and customer satisfaction, we proudly serve clients across India, the USA, and Germany.