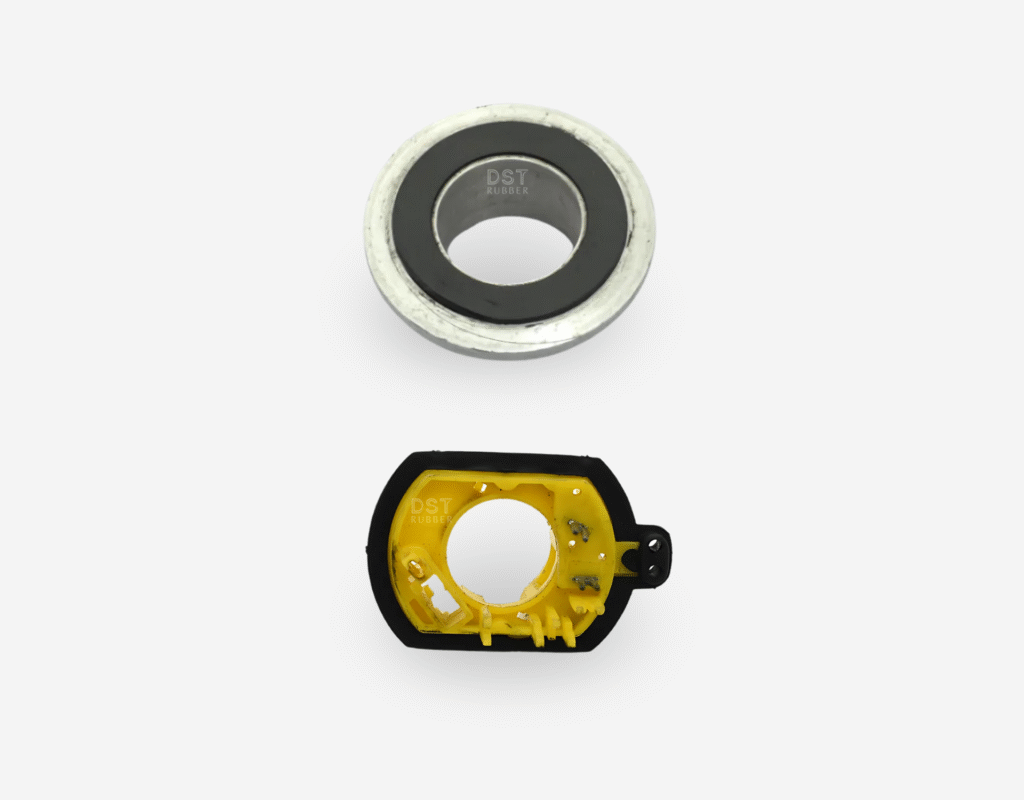

DS Techno Rubber

What we Believe In

DS Techno Rubber dedicates significant resources to defect prevention, identification elimination during manufacturing, resulting in an low rejection rate from our customers. In-process testing is integral to our manufacturing process, conducted routinely. Utilizing precise testing facilities, they implement a rigorous testing protocol for all our manufactured components.

DST maintains an internal mixing facility to guarantee consistency in their compound and fulfills all quality criteria specified by their customers. Their operations align with the IATF 16949 standard, and they meticulously comply with its requirements.

DS Techno Rubber team’s commitment to continuous improvement and proactive problem-solving enables them to plan and swiftly address any unforeseen challenges, maintaining their promise of punctuality and reliability for every delivery.

With over 35 years of expertise, DS Techno Rubber has built a reputation for delivering precision-engineered rubber components through a tightly controlled and innovation-driven manufacturing process.

From compound formulation to final inspection, every stage is optimized in-house to ensure quality, consistency, and compliance with global standards.Trusted by OEMs and industries across India and abroad, our process reflects our commitment to excellence in every part we produce.

Our 3-Step Process to Precision

We use an in-house mixing facility and automated weighing systems to ensure consistent, high-quality rubber compounds tailored to your needs.

Custom rubber molding based on designs or samples, with expertise in producing intricate, high-quality components for all applications.

Thorough quality checks at every stage ensure consistent product performance and adherence to strict industry standards.

Proud Partnerships with Industry Leaders

We have state-of-the-art, In-House Facilities

- Chemical Weighing

- Dispersion Kneader

- Two Roll Mill

- Preformer

- Calendar

- Hydraulic Press

- Finishing Machines

- Rheometer

- Digital Tensile Testing Machine

- Accelerated Ageing Oven

- Fabric / Metal to Rubber Adhesion Tester

- Compression Set Resistance Apparatus

- Volume Swell Test

- Diaphragm Leak Test Fixture

- Functional Life Tester

- Melting Point Apparatus

- Specific Gravity Balance

- Hydrometer

- Low Temperature Cabinet

- Hot Air Oven

- Universal Testing Machine

- Video Measuring System