Chemical Properties of Rubber

Chemical Testing Overview

Purpose

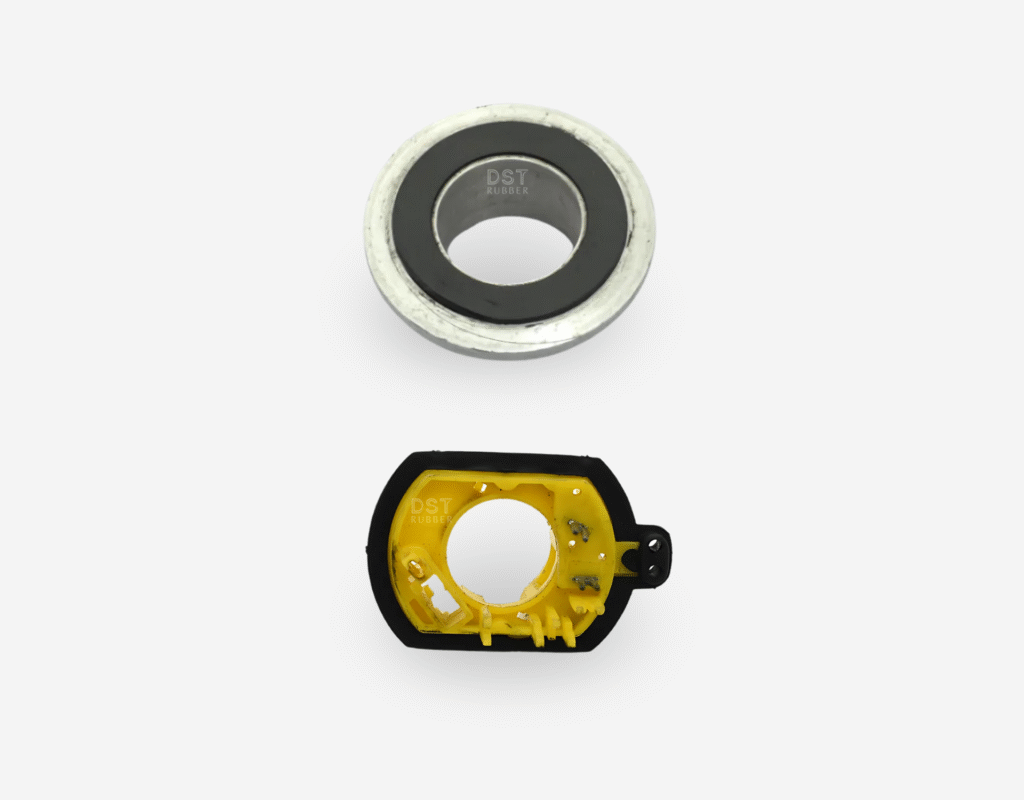

Rubber components used in machinery, engines, and hydraulic systems often come in contact with oils and fluids. Oil swell testing measures how rubber reacts to such exposure.

Key Highlights

- Tested as per ASTM D471 and ISO 1817 standards.

- Samples are immersed in specific oils/fluids to simulate service conditions.

- Changes in volume, hardness, tensile strength, and elongation are monitored.

- Beyond swelling, the test reveals chemical degradation that affects long-term reliability.

- Helps predict performance and compatibility in applications like gaskets, seals, and bushings.

Purpose

Rubber materials used outdoors or in industrial settings must resist ozone-induced cracking and degradation.

Key Highlights

- Ozone interacts with rubber’s polymer chains, leading to surface cracks and oxidation.

- Critical for sealing components, hoses, weatherstrips, and aerospace parts.

- Test performed in a sealed ozone chamber at controlled temperature and humidity.

- Exposure time ranges from 72 hours to several weeks, based on application.

- Post-test evaluation includes visual inspection for cracks and mechanical testing for changes in tensile strength.

Purpose

To simulate years of natural ageing within days or weeks, this test evaluates how rubber compounds respond to environmental stressors over time.

Key Highlights

- Samples are subjected to elevated temperatures, UV light, ozone, and humidity.

- Identifies changes in elasticity, hardness, brittleness, and chemical structure.

- Helps determine material durability and predict service life under harsh conditions.

- Ensures rubber does not lose performance in extreme climates or long-term exposure.

Proud Partnerships with Industry Leaders

DS Techno Rubber

35

Experience

iatf 16949 certified

DST is a trusted manufacturer with over 35 years of expertise in producing technically complex rubber components. IATF 16949 certified and recognized for excellence, we specialize in innovative solutions, ensuring top-quality products for automotive and non-automotive sectors.

With a strong focus on research and development, quality control, and customer satisfaction, we proudly serve clients across India, the USA, and Germany.