Engineering Precision for Lasting Performance

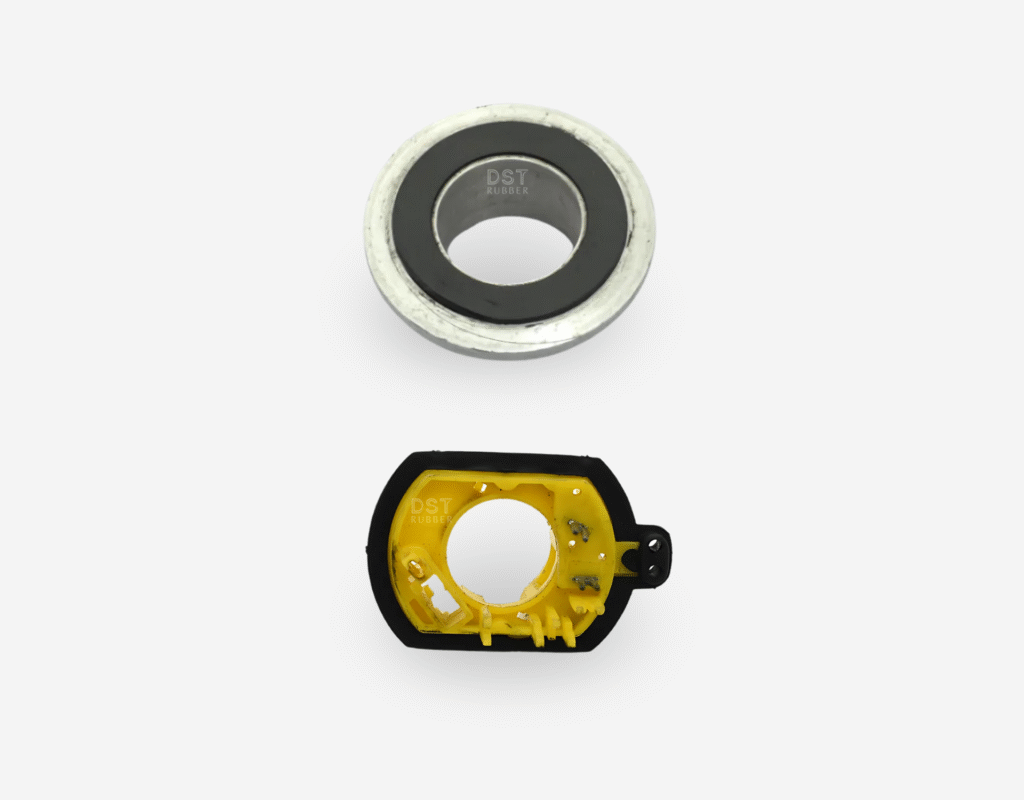

DST Rubber delivers engineering excellence through advanced material selection, precision moulding, and rigorous testing. Serving automotive, fluid control, and energy sectors, we create high-performance rubber components that meet complex industrial challenges. With decades of expertise, we ensure consistent performance, durability, and reliability, helping industries across India and worldwide achieve long-term value in demanding environments.

Rubber Properties

Material Characteristics

Reinforcement

Proud Partnerships with Industry Leaders

DS Techno Rubber

35

Experience

iatf 16949 certified

DST is a trusted manufacturer with over 35 years of expertise in producing technically complex rubber components. IATF 16949 certified and recognized for excellence, we specialize in innovative solutions, ensuring top-quality products for automotive and non-automotive sectors.

With a strong focus on research and development, quality control, and customer satisfaction, we proudly serve clients across India, the USA, and Germany.