Metal Reinforcement in Rubber Diaphragms

Metal reinforcement enhances rubber diaphragms by combining the flexibility of rubber with the rigidity and strength of metals such as steel, aluminum, or brass. This composite structure is designed for high-load and high-precision environments, making it ideal for applications that demand structural stability, shape retention, and vibration control.

The metal insert ensures precise mounting and dimensional stability while distributing stress evenly across the diaphragm. This results in longer service life, enhanced sealing, and resistance to mechanical deformation. At DS Techno Rubber, we engineer these diaphragms with precision bonding techniques and optimized rubber flow to eliminate common manufacturing flaws and ensure consistent quality for automotive, railways, and industrial systems.

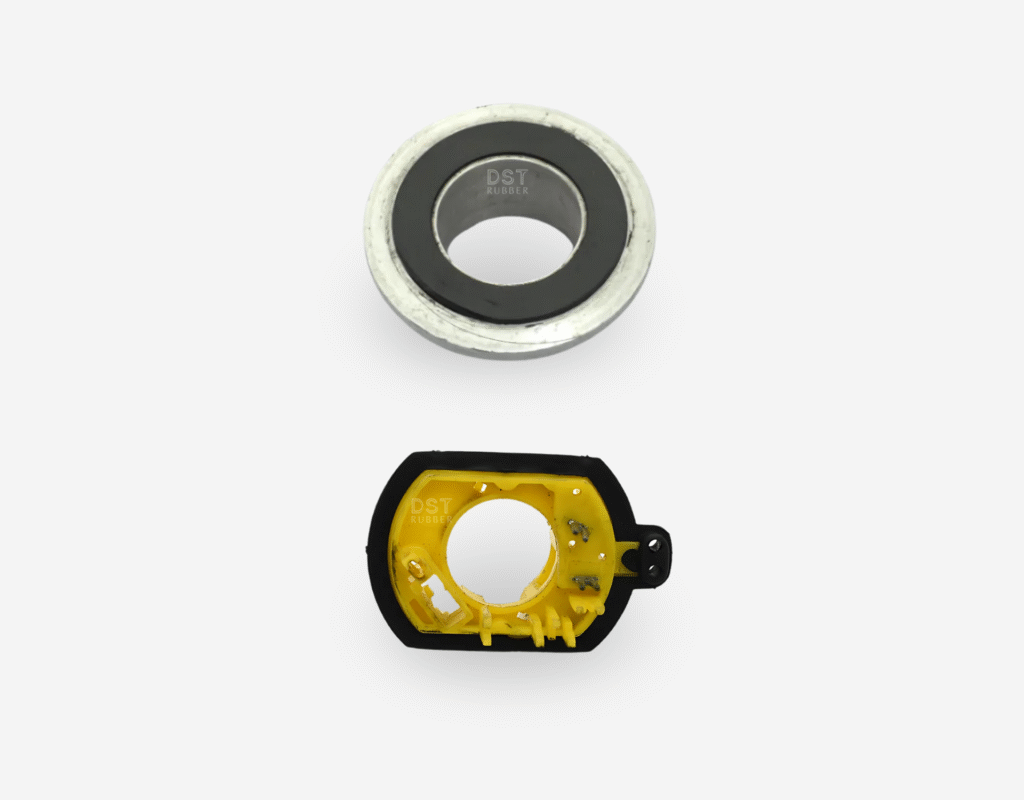

Diaphragms with Centrally Placed Metal Inserts

When metal is embedded at the center of the diaphragm, it provides enhanced structural support while preserving the flexibility of the rubber around it. This configuration allows the diaphragm to handle mechanical loads without losing sealing efficiency or dimensional accuracy.

The central reinforcement ensures precise fitment in assemblies, making it ideal for engine mounts, anti-vibration systems, and pump gaskets. The added rigidity helps distribute pressure evenly and improves fatigue resistance under repetitive mechanical cycles, delivering long-term performance even in harsh environments.

Diaphragms with Surface-Bonded Metal Layers

Surface-bonded metal layers provide added stiffness and structural support, allowing secure attachment through welding, bolting, or press-fit. This design ensures dimensional stability under load, making it ideal for rugged applications requiring precise diaphragm alignment.

The bonded metal layer improves mounting accuracy, distributes mechanical stress evenly, and resists permanent deformation. These diaphragms are used in equipment like compressors, suspension bushings, and industrial press pads where shape retention and load-bearing are essential.

Proud Partnerships with Industry Leaders

DS Techno Rubber

35

Experience

iatf 16949 certified

DST is a trusted manufacturer with over 35 years of expertise in producing technically complex rubber components. IATF 16949 certified and recognized for excellence, we specialize in innovative solutions, ensuring top-quality products for automotive and non-automotive sectors.

With a strong focus on research and development, quality control, and customer satisfaction, we proudly serve clients across India, the USA, and Germany.