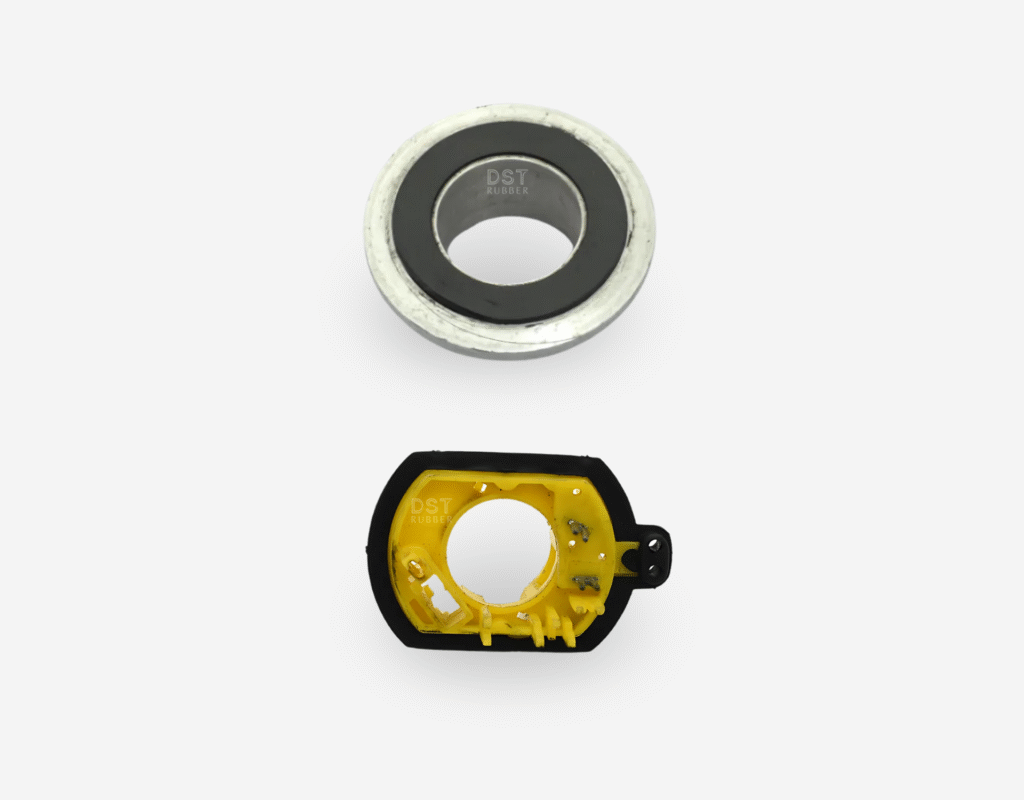

O Rings

High-Quality O-Rings for Reliable Sealing Solutions

At DS Techno Rubber, we specialize in manufacturing O-rings designed to provide effective sealing in a wide range of applications. Our O-rings offer excellent resistance to aggressive fluids, oils, gases, and high temperatures, ensuring long-lasting performance and preventing costly downtime and maintenance. .

O-rings sizes from 1 mm to 350 mm OD

Capable of withstanding -40°C to 200°C

with optimal elasticity & compression set

What Are O-Rings?

O-rings are essential sealing components used in various industries to provide airtight, waterproof, and leak-proof seals. They prevent fluid and gas leaks, ensuring system efficiency and protection in high-pressure, high-temperature environments.

Automotive

Oil and Gas

Food and Beverage

Industrial Machinery

Our Products

We offer a wide range of high-quality O-rings designed to provide reliable sealing solutions for various industries, ensuring optimal performance, durability, and efficiency in every application

Standard O-Rings

Reliable, high-performance sealing solutions for general applications in automotive, machinery, and fluid systems.

Custom O-Rings

Tailored O-rings designed to meet specific application requirements, with custom sizes, materials, and hardness.

Food-Grade O-Rings

O-rings manufactured to meet FDA and NSF standards, ensuring safety and reliability in the food, beverage, and pharmaceutical industries.

Types of O-Rings

We offer a diverse range of O-rings to meet the unique sealing needs of various applications. From standard O-rings to specialized options like V-rings and food-grade O-rings, each type is engineered to provide superior performance in dynamic and static sealing environments.

X-Rings

Square O-Rings

V-Rings

Vacuum O-Rings

High-Temperature O-Rings

Capable of withstanding temperatures up to 200°C, perfect for automotive, industrial, and aerospace applications.

Low-Temperature O-Rings

Designed for extreme cold environments, these O-rings perform well at temperatures as low as -40°C.

Oil-Resistant O-Rings

Why Choose DS Techno Rubber O-Rings?

Precision Engineering

Every O-ring is manufactured with precise dimensional accuracy using advanced measurement technologies like the 67x zoom Video Measuring System (VMS).

Wide Range of Materials and Sizes

Customization to Meet Your Specific Needs

Whether you need custom sizes, hardness, or specialized O-rings like food-grade or vacuum seals, we can tailor our products to meet your precise application requirements.

High Manufacturing Capacity

Ability to produce up to 200,000 O-rings per day to meet large-scale production demands.

Features of Our O-Rings

Temperature Resistance

Chemical Resistance

Excellent Durability

Leak-Proof Seal

Provides an airtight, waterproof, and leak-proof seal to prevent damage, downtime, and maintenance.

Proud Partnerships with Industry Leaders

Custom O-Rings for your Needs

Industries We Serve

Automotive

Instrumentation and Sensors

Industrial and OEM Applications

Renewable Energy (Windmills)

Hydraulic and Pneumatic Systems

Why DS Techno Rubber?

35+ Years of Expertise

We bring decades of experience in designing and manufacturing custom rubber components.

Precision Engineering

Each diaphragm is crafted with the highest level of attention to detail.

Superior Materials

We use only the finest rubber compounds to ensure durability and performance.

Global Reach

Serving industries in India, the USA, and Germany with high-quality products and on-time delivery.

Frequently Asked Questions (FAQ) about O-Rings

O-rings are essential sealing components used across a variety of industries, including automotive, aerospace, plumbing, hydraulics, pneumatics, and medical devices. They provide a leak-proof seal in applications such as engines, pumps, valves, fuel systems, and industrial machinery, preventing fluid or gas leakage under various pressure and temperature conditions.

- Nitrile (NBR): Ideal for automotive and industrial use, resistant to oils and fuels.

- Viton® (FKM): Offers high-temperature and chemical resistance for harsh industrial conditions.

- EPDM: Excellent for water, steam, and weathering resistance.

- Silicone: Offers high flexibility and temperature resistance, widely used in medical and food applications.

- Neoprene: Known for weather, oil, and ozone resistance, suitable for general-purpose sealing.

- Material compatibility with the fluid, chemicals, and temperature involved.

- Size and hardness (durometer) for a proper seal and optimal compression.

- Pressure requirements for both static and dynamic sealing applications.

- Operating temperature range for high-heat or cold environments.

- Incorrect material selection that doesn’t match the chemicals or temperature.

- Over-compression or improper installation, leading to cracks or deformation.

- Abrasion or excessive wear from friction in dynamic applications.

- Swelling or hardening due to exposure to incompatible fluids.

- Thermal degradation from exposure to extreme temperatures.

To maximize the lifespan of O-rings:

- Choose the correct material tailored to the specific application.

- Lubricate O-rings properly to reduce friction and wear.

- Ensure proper installation to avoid over-compression or stretching.

- Store O-rings in a cool, dry place, away from direct sunlight and ozone exposure.

- Regularly inspect O-rings and replace any worn or damaged ones before failure.

Get a Custom Quote

Looking for high-quality custom rubber components? We’re here to provide you with tailored solutions that meet your exact requirements. Simply fill out the form below, and we’ll provide a personalized quote based on your specifications.