Physical Properties of Rubber

Understanding the physical properties of rubber is essential for designing components that perform under pressure, flex, and stress. From tensile strength and hardness to compression set and dimensional tolerance, these properties influence durability, sealing efficiency, and long-term reliability.

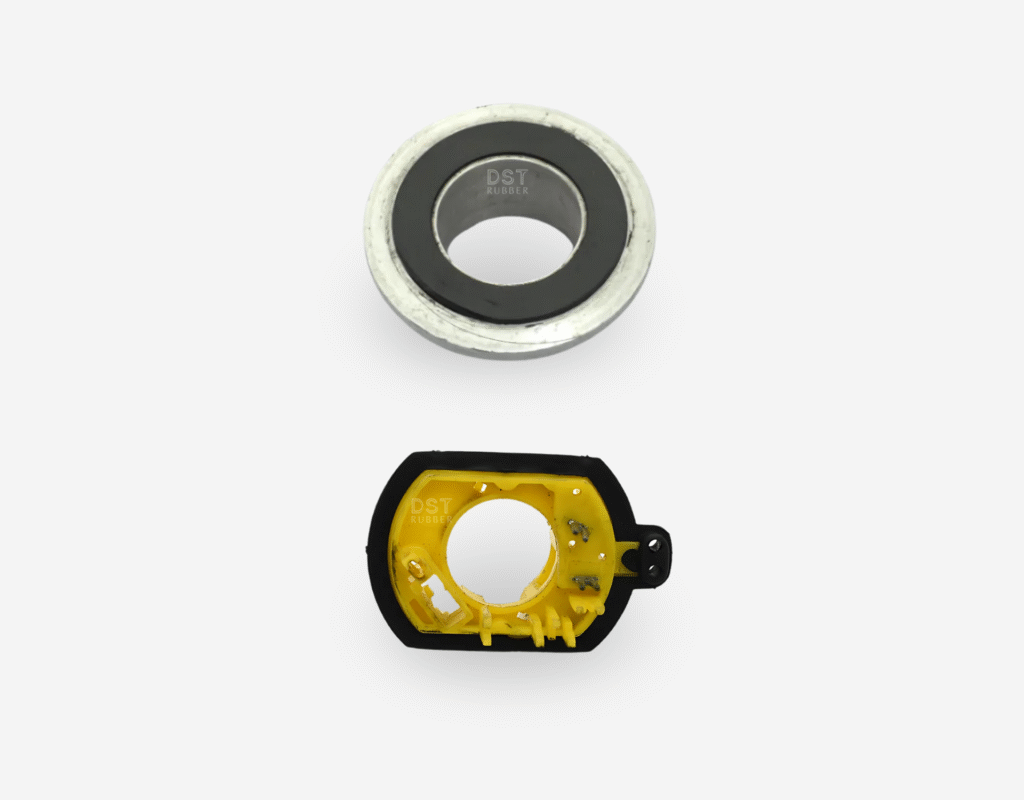

At DST Rubber, we engineer every product with precision to meet demanding industrial requirements.

Understanding Modulus

Modulus, often expressed through Young’s Modulus (E), defines how rubber responds to tensile stress. It represents the ratio between stress and strain along a specific axis, offering insights into the material’s elastic behavior under load.

Why Modulus Matters

Rubber components, especially elastomers, play a critical role in vibration damping and noise isolation. In many applications, they’re bonded between rigid surfaces and subjected to compression. To predict their performance, it’s essential to understand key material properties like Poisson’s ratio, damping coefficient, and modulus of elasticity.

Testing and Quality Control

Modulus testing helps evaluate how rubber behaves under thermal and chemical exposure, ensuring product reliability over time. For long-term performance, property retention is more important than individual values such as elongation or tensile strength.

How It's Measured

Unlike metals, elastomers do not show a linear relationship between stress and strain. The modulus of rubber indicates a specific point on the stress-strain curve, rather than a fixed slope. This characteristic must be considered during design and analysis.

Interconnected Properties

The bulk modulus (K) quantifies how rubber resists volume changes under compression and is calculated using:

K = p / ev

Where:

p = Hydrostatic pressure

ev = Volumetric strain

Modulus values also relate closely to other mechanical constants such as Poisson’s ratio (v) and shear modulus (G), giving a fuller picture of rubber’s mechanical behavior under varying loads.

What Is Elongation?

Elongation refers to how much a rubber material can stretch before it breaks, measured as a percentage of its original length. For example, if a rubber component stretches to twice its initial length before failure, the elongation is recorded as 100%.

Why It Matters

Evaluating the tensile strength and elongation of elastomers is critical to understanding their mechanical performance. These properties help determine how much force a material can withstand before rupture and how far it can stretch without failure—both essential for selecting the right rubber compound for specific applications.

How It's Measured

Testing is conducted using a dynamometer, which applies force to a rubber sample until it breaks. The test accounts for variables such as temperature, humidity, and preconditioning, all of which influence stress-strain behavior. In some cases, O-ring samples are rotated during testing to prevent uneven stress concentration.

Calculating Elongation

Elongation is calculated using the following formula:

Elongation (%) = (Elongation at break × 100) / Original gauge length

Only the change in length within the marked gauge area is considered for accurate results.

Result Interpretation

The final elongation value is typically reported as a percentage with two significant figures, offering a standardized way to compare rubber materials.

What Is Hardness (DH)?

Hardness in elastomers refers to their resistance to permanent indentation when a force is applied. This property is measured using a durometer, an instrument that evaluates how much a material resists surface penetration.

Durometer Scales & Rubber Types

Rubber hardness is categorized using different durometer scales, based on material types and firmness levels:

| Scale | Material Type | Typical Range |

|---|---|---|

| A | Soft vulcanized rubber, natural rubber, TPEs | 20–90 A |

| B | Moderately hard rubber and TPEs | >90 A, <20 D |

| C | Medium-hard rubber and TPEs | >90 B, <20 D |

| D | Hard rubber and TPEs | >90 A |

| DO | Moderately hard rubber and TPEs | >90 C, <20 D |

| M | Thin rubber sheets and thermoplastics | 20–85 A |

| O | Very soft rubber and elastomers | <20 DO |

| OO | Extremely soft rubber or gel-like materials | <20 O |

How It’s Measured

A durometer measures indentation depth by applying a standardized force through a shaped presser foot. The result is influenced by:

- Presser foot geometry

- Duration of force application

- Rubber’s viscoelasticity

- Sample stiffness (modulus)

The standard test follows ASTM D2240 guidelines, ensuring uniformity and reliability. In timed tests, force is applied for a fixed duration before measurement is recorded.

Factors Influencing Hardness

Hardness readings depend on both the indentor shape and applied pressure. While useful for quality control, these values are not direct indicators of a rubber’s inherent mechanical properties like elasticity or modulus.

Elastic Modulus Correlation

There is a correlation between durometer hardness and Young’s modulus (E). For example:

- SA = Type A hardness

- SD = Type D hardness

This relationship helps engineers estimate modulus from hardness data during design evaluations.

What Is Compression Set?

Compression Set (CS) is the measure of permanent deformation in a rubber component after a compressive force is removed. It indicates the material’s ability to recover its original thickness after being compressed for a specific time and temperature.

Why It Matters

CS is a critical factor in applications requiring long-term sealing performance, such as gaskets, O-rings, and vibration isolation pads. A high compression set may result in seal failure or reduced cushioning ability—compromising reliability in demanding environments.

Understanding the Measurement

If a rubber sample fully recovers after compression, it has 0% CS. If it retains all its deformation, it shows 100% CS. CS testing follows ASTM D395 and involves two primary test methods:

1. Test Method A – Compression Under Constant Force

- A constant force (typically 1.8 kN) is applied at a defined temperature and time.

- Commonly used for general rubber samples.

2. Test Method B – Compression Under Constant Deflection

- The sample is compressed to 25% of its original height and held at temperature.

- Often used for materials needing consistent deformation resistance.

Additionally, O-ring compression set testing is performed using ASTM D1414 B for accurate sealing performance validation.

How It's Calculated

Each method uses a distinct formula:

Method A:

CA = [(to – ti) / to] × 100

CA: Compression Set A

to: Original thickness

ti: Thickness after recoveryMethod B:

CB = [(to – ti) / (to – tn)] × 100

CB: Compression Set B

tn: Thickness under compression

Testing Standards & Consistency

CS tests are typically conducted for a minimum of 30 minutes after removing load, under standard atmospheric conditions, to ensure meaningful results. These insights help DST Rubber ensure that our rubber compounds meet high-performance sealing and durability requirements across industries.

What Is Dimensional Tolerance?

Dimensional tolerance refers to the acceptable range of variation in a rubber product’s physical dimensions—such as thickness, diameter, or length—when compared to its design specifications. It ensures that even with slight differences in manufacturing, the product remains fit for function.

Why It Matters

Due to the flexible and compressible nature of rubber, maintaining consistent dimensions during molding and curing can be challenging. Dimensional tolerance plays a critical role in:

- Ensuring proper fit and sealing in assemblies

- Maintaining interchangeability across batches

- Achieving quality assurance in precision-based industries

For products like O-rings, gaskets, and bonded parts, tight tolerances are crucial to avoid leaks, mechanical failures, or alignment issues.

Factors Influencing Rubber Tolerances

Unlike metals or plastics, rubber components are affected by several variables:

Shrinkage during cooling

Material type and hardness

Mold design and part geometry

Curing process and temperature

These make achieving uniform dimensions more complex, which is why tolerance bands are specified based on industry standards.

Standards Followed

At DST Rubber, we follow globally accepted tolerance standards, including:

ISO 3302-1 for general rubber products

RMA (Rubber Manufacturers Association) Classifications

Class A (High Precision)

Class B (Precision)

Class C (Commercial)

Each class defines tolerance ranges for dimensions like:

Parting line flash

Cross-sections

Inside and outside diameters

Length and width

Types of Tolerance in Rubber Products

- Molded Part Tolerances – Defined by part complexity and shrink characteristics.

- Extruded Product Tolerances – Often tighter for cross-sections and profiles.

- Bonded Rubber-to-Metal Parts – Require combined consideration of both metal and rubber dimensional behavior.

Quality Assurance at DST Rubber

Every part we produce undergoes precise inspection using calibrated tools to ensure dimensional consistency. Whether it’s a custom gasket or a vibration isolator, DST Rubber maintains strict adherence to tolerance bands that align with customer application requirements.

Proud Partnerships with Industry Leaders

DS Techno Rubber

35

Experience

iatf 16949 certified

DST is a trusted manufacturer with over 35 years of expertise in producing technically complex rubber components. IATF 16949 certified and recognized for excellence, we specialize in innovative solutions, ensuring top-quality products for automotive and non-automotive sectors.

With a strong focus on research and development, quality control, and customer satisfaction, we proudly serve clients across India, the USA, and Germany.