Rubber Bellows

Engineered Rubber Bellows for Industrial Sealing and Movement Compensation

We provide a wide selection of rubber bellows built to isolate vibration, accommodate movement, and protect mechanical components from dust, moisture, and pressure fluctuations.

Available in rubber types like NR, NBR, EPDM, VMQ, FKM

Operate across -40°C to 200°C temperature range

Perform under both static and dynamic conditions

What Are Rubber Bellows?

Rubber bellows (also called as expansion joints) are flexible connectors designed to absorb vibration, compensate for movement, and seal mechanical components from dust, moisture, and pressure. They are essential in systems where protection, flexibility, and leak prevention are critical.

Automotive

Industry

Safeguard CV joints, steering systems, and suspensions from dust and moisture.

Piping & Ducting Systems

Absorb expansion, vibration, and misalignment in pipelines and ductwork.

Hydraulic & Pneumatic Systems

Prevent fluid leaks and allow smooth movement in actuators and cylinders.

Industrial

Machinery

Shield shafts, rods, and joints from external contaminants and mechanical wear.

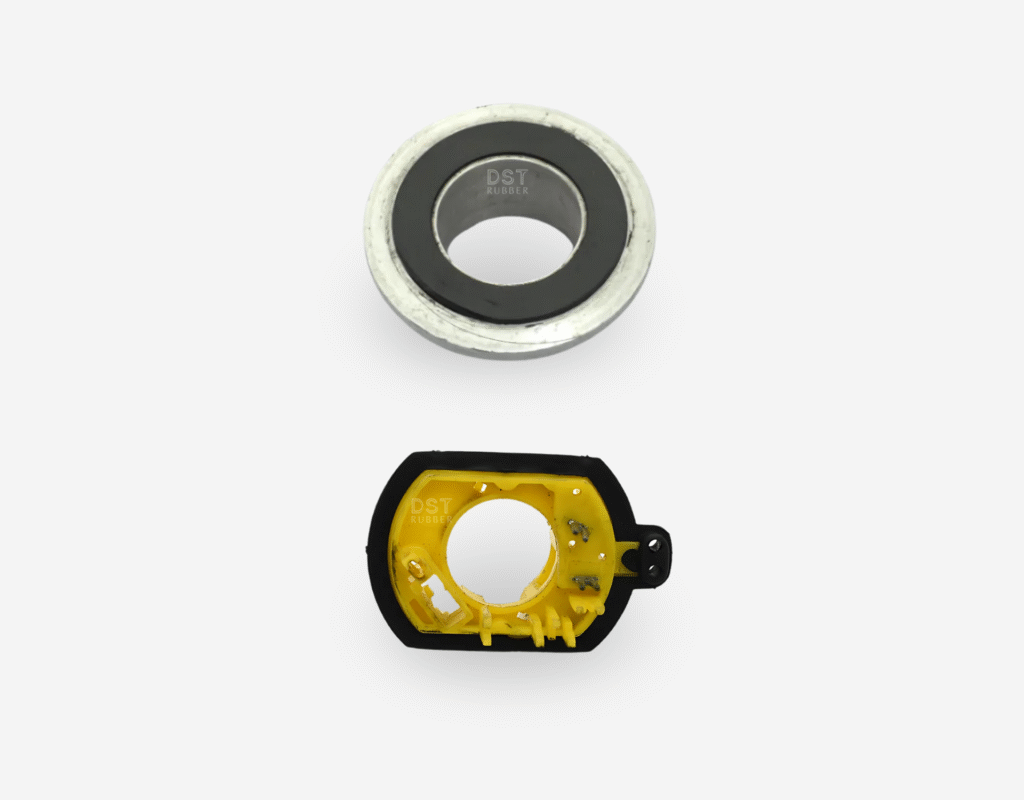

Our Products

We offer a wide range of rubber bellows designed for various industrial applications and system requirements

Expansion

Bellows

Designed to absorb thermal expansion, vibration, and axial movement while preventing structural stress in industrial piping and duct systems.

Protective Shaft Bellows

Used to protect shafts, rods, and mechanical joints from dust, debris, moisture, and physical damage during continuous or high-speed operation.

Flexible Connector Bellows

Installed between ducting or piping to handle misalignment, minimize vibration transmission, and improve flexibility under varying operating conditions.

Vacuum

Bellows

Provide airtight flexibility in vacuum systems, allowing precise motion while maintaining pressure integrity in scientific and industrial environments.

Types of Rubber Bellows

We offer a wide range of rubber bellows designed for various applications, each built for precision, durability, and system compatibility.

Expansion Bellows

Absorb thermal expansion, vibration, and axial movement in piping systems to prevent stress and failure.

Protective Shaft Bellows

Shield shafts and joints from dust, debris, and contaminants, ensuring safe operation and extended service life.

Flexible Connector Bellows

Accommodate misalignment and reduce vibration transmission between connected pipes or ducts in dynamic systems.

Vacuum Bellows

Maintain airtight seals while allowing controlled movement in vacuum chambers and sensitive instrumentation applications.

Convoluted Bellows

Feature deep folds for enhanced flexibility and compression in compact spaces or high-motion environments.

Rectangular Bellows

Designed for flat or rectangular systems to protect sliding mechanisms and linear motion components effectively.

Molded Rubber Bellows

Custom-molded to meet specific shapes, dimensions, and performance needs across various sealing applications.

Fabric-Reinforced Bellows

Built with layered fabric to improve strength, flex life, and pressure resistance in demanding industrial conditions.

Why Choose DS Techno Rubber Bellows?

Application-Focused Design

Every bellow is tailored to meet specific system needs. Movement, sealing, temperature, or pressure compensation.

Material

Versatility

We offer bellows in multiple rubber types to match diverse industrial and environmental conditions.

Precision Manufacturing

Our tooling, testing, and production ensure tight tolerances and consistent quality across all product batches.

Performance You Can Rely On

From dynamic machinery to static systems, our bellows deliver repeatable performance and long-lasting durability.

Features of Our Bellows

High Flexibility and Strength

Withstand constant motion and stress without cracking, tearing, or losing form over time.

Noise and Vibration Dampening

Reduces transmitted noise and vibration across systems, improving performance and user comfort in industrial applications.

Contaminant Protection

Effectively seal out dust, moisture, chemicals, and other contaminants that compromise system integrity.

Dynamic Load Compatibility

Engineered to handle vibration, expansion, and movement in systems operating under dynamic or fluctuating conditions.

Proud Partnerships with Industry Leaders

Custom Rubber Bellows for your Needs

Get in touch today to discuss custom Rubber Bellows tailored to your precise needs!

Industries We Serve

Automotive

Instrumentation and Sensors

Industrial and OEM Applications

Renewable Energy (Windmills)

Hydraulic and Pneumatic Systems

Why DS Techno Rubber?

35+ Years of Expertise

We bring decades of experience in designing and manufacturing custom rubber components.

Precision Engineering

Each diaphragm is crafted with the highest level of attention to detail.

Superior Materials

We use only the finest rubber compounds to ensure durability and performance.

Global Reach

Serving industries in India, the USA, and Germany with high-quality products and on-time delivery.

Frequently Asked Questions (FAQ) about Rubber Bellows

Rubber bellows are flexible connectors designed to absorb vibration, compensate for movement, and protect mechanical components from dust, moisture, and contaminants. In India, they are widely used in automotive, industrial machinery, pumps, and piping systems to ensure long-lasting sealing and operational reliability.

Rubber bellows are manufactured from elastomers such as EPDM, NBR, Neoprene, Silicone, and FKM, depending on application requirements. Material selection is based on factors like temperature range, chemical compatibility, UV resistance, and flexibility. DS Techno Rubber engineers each bellow compound to match the specific industrial and environmental conditions of the project.

When selecting rubber bellows, consider:

Operating temperature and pressure requirements.

Compatibility with the fluids, gases, or contaminants present.

Movement type and range, including axial, lateral, or angular deflection.

Space constraints and mounting method.

Relevant industry standards and certifications for the application.

Common failure causes include incorrect material choice, overextension or compression, misalignment during installation, chemical attack, and environmental degradation from UV or ozone exposure. Selecting the correct material and ensuring proper installation greatly reduces the risk of premature failure.

To maximize service life:

Use the correct material for the application.

Ensure proper installation and alignment to avoid excessive strain.

Protect from direct UV, ozone, or harsh chemicals when possible.

Follow preventive maintenance schedules and replace worn units promptly.

Get a Custom Quote

Looking for high-quality custom rubber components? We’re here to provide you with tailored solutions that meet your exact requirements. Simply fill out the form below, and we’ll provide a personalized quote based on your specifications.