Rubber Gaskets

Reliable Sealing Solutions for Diverse Applications

At DS Techno Rubber, we provide high-quality rubber gaskets designed for effective sealing, vibration control, and weatherproofing in a wide range of industries.

Chemical & Corrosion Resistance

Withstand FDA Approved Compounds

Customizable to Any Shape

What Are Rubber Gaskets?

Rubber gaskets are sealing components used to prevent the leakage of gases or fluids between two surfaces. Made from flexible materials, they are used to create a tight, reliable seal that can withstand varying temperature, pressure, and environmental conditions. Rubber gaskets are commonly used in industries ranging from automotive to industrial machinery, offering benefits such as vibration control, shock absorption, and moisture resistance.

Automotive Industry

Industrial Machinery & Pipelines

HVAC & Refrigeration

Medical & Food Processing

Built with FDA-approved compounds to maintain hygiene and prevent contamination.

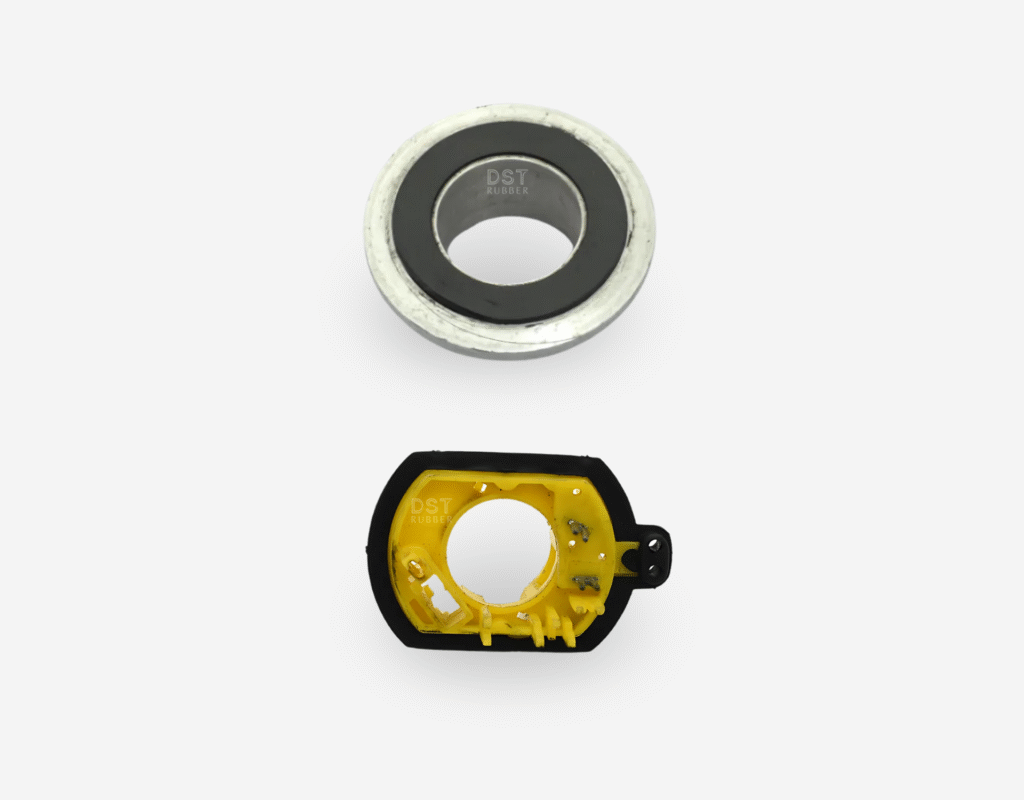

Our Products

We specialize in manufacturing a wide variety of rubber gaskets tailored to meet the specific needs of various industries. Our gaskets are designed for reliable sealing, providing efficient solutions for high-pressure, high-temperature, and demanding applications. We offer the following types of rubber gaskets:

Flange Gaskets

Manifold Gaskets

Commonly found in automotive exhaust & intake systems providing reliable sealing for critical engine components.

Lid & Cover Gaskets

Weatherproofing Gaskets

Custom Gaskets

Rubber Gasket Materials

At DS Techno Rubber, we design and manufacture rubber gaskets using various materials based on specific application requirements, ensuring optimal sealing performance under different conditions.

Nitrile Rubber (NBR)

Ideal for oil, fuel, and chemical resistance, commonly used in automotive and industrial applications.

Viton® (FKM)

Offers high-temperature and chemical resistance, perfect for harsh industrial and extreme environments.

EPDM

Resistant to water, steam, and ozone, making it suitable for weatherproofing and outdoor applications.

Silicone

Known for high flexibility and temperature resistance, ideal for medical and food processing.

Neoprene

Provides weather, oil, and ozone resistance, used for general-purpose sealing in various industries.

Fluorosilicone

Exceptional fuel and oil resistance, perfect for aerospace, automotive, and other high-demand industries.

Polyurethane

Known for abrasion resistance and high tensile strength, ideal for high-wear industrial applications.

Natural Rubber

Provides flexibility and resilience, suited for moderate-pressure applications with moderate environmental stress.

Why Choose DS Techno Rubber for Manufacturing Gaskets?

We take pride in producing high-quality rubber gaskets designed to meet the specific requirements of various industries. Our expertise, precision, and dedication to innovation make us the ideal choice for your sealing needs.

Custom Manufacturing

We offer custom gaskets tailored to your exact specifications, ensuring a perfect fit and optimal sealing performance in every application.

Wide Range of Materials

We provide a variety of rubber materials, including Nitrile, EPDM, Viton®, Silicone, and more, to suit diverse sealing needs, from automotive to food-grade applications.

High-Precision Engineering

Our gaskets are manufactured with strict dimensional tolerances to ensure a precise seal and reliable performance across different industries.

Industry Certifications

Our products are REACH, RoHS compliant, and we use FDA-approved compounds for food safety, ensuring compliance with the highest industry standards.

Features of Our Gaskets

Reliable

Sealing

Our gaskets offer airtight, waterproof, and leak-proof seals

Wide Temperature

Range

Our gaskets operate efficiently within a wide temperature range from -40°C to 200°C

High Abrasion &

Tear Resistance

Manufactured to resist wear & tear, our gaskets are ideal for high-friction & mechanical stress applications.

Weather & Environmental Resistance

Designed to withstand moisture, dust, and UV exposure, our gaskets provide effective sealing and weatherproofing.

Proud Partnerships with Industry Leaders

Custom Rubber Gaskets for your Needs

Rubber Gasket Materials

At DS Techno Rubber, we design and manufacture rubber gaskets using various materials based on specific application requirements, ensuring optimal sealing performance under different conditions.

Nitrile Rubber (NBR)

Neoprene

Polyurethane

EPDM

Fluorosilicone

Natural Rubber

Why DS Techno Rubber?

35+ Years of Expertise

We bring decades of experience in designing and manufacturing custom rubber components.

Precision Engineering

Each diaphragm is crafted with the highest level of attention to detail.

Superior Materials

We use only the finest rubber compounds to ensure durability and performance.

Global Reach

Serving industries in India, the USA, and Germany with high-quality products and on-time delivery.

FAQ

Rubber gaskets are sealing components used to prevent leakage of gases or fluids between two surfaces. They are commonly used in automotive, industrial, plumbing, and HVAC applications to ensure airtight, waterproof, and leak-proof seals.

Rubber gaskets are made from various elastomers, including Nitrile (NBR), EPDM, Silicone, Neoprene, and Viton®, depending on the application. The material choice is based on factors like chemical exposure, temperature range, and mechanical stress.

To choose the correct material, consider:

- Temperature resistance: Select materials suitable for high or low temperatures.

- Chemical compatibility: Ensure the material is resistant to the fluids or gases being sealed.

- Pressure and sealing requirements: Choose based on static or dynamic sealing needs.

- Food-grade or medical: Ensure compliance for food or medical applications.

Rubber gasket performance is affected by:

- Material compatibility with the fluids being sealed.

- Compression set: How well the gasket retains its shape under pressure.

- Operating temperature and pressure.

- Proper installation and surface finish to ensure an effective seal.

To prolong the lifespan of rubber gaskets:

- Use the correct material for your specific application.

- Ensure proper installation to avoid over-compression or stretching.

- Regularly inspect and replace worn or damaged gaskets.

- Avoid exposure to extreme conditions that exceed the gasket’s temperature or chemical resistance.

Yes, DS Techno Rubber offers custom rubber gaskets in various shapes, sizes, and materials tailored to your specific needs. Whether for industrial, automotive, or food-grade applications, we ensure the gasket meets your exact requirements.

- Static rubber gaskets are used in applications where there is no movement between the surfaces, such as pipe joints.

- Dynamic rubber gaskets are designed for applications where movement occurs, such as in rotating shafts or hydraulic seals.

Get a Custom Quote

Looking for high-quality custom rubber components? We’re here to provide you with tailored solutions that meet your exact requirements. Simply fill out the form below, and we’ll provide a personalized quote based on your specifications.