Rubber Grommets

High-Performance Rubber Grommets for Sealing and Vibration Damping

DS Techno Rubber grommets come in various types, including protective grommets for wire shielding, sealing grommets for moisture and dust prevention, and vibration-damping grommets for shock and noise reduction.

Superior Vibration Damping

Electrical Insulation

Protection Against Mechanical Damage

What are Rubber Grommets?

Rubber grommets are essential components used to protect and insulate wires, cables, and tubes from damage caused by sharp edges, vibrations, and other environmental factors. Made from high-quality elastomers, rubber grommets provide mechanical protection, vibration reduction, and sealing, ensuring smooth operation in automotive, electronics, and industrial systems. They help prevent damage from wear and tear, reduce stress fractures, and protect sensitive components from harsh environmental conditions, such as moisture, dust, and UV exposure.

Automotive & Transportation

Rubber grommets protect automotive systems, ensuring insulation, vibration damping, and abrasion resistance, enhancing vehicle safety, and extending system longevity.

Electronics & Electrical Enclosures

Rubber grommets offer insulation, strain relief, and protection in electronics, preventing abrasion, short circuits, and contamination for reliable performance.

Industrial Machinery

Rubber grommets in machinery protect wires from vibration, abrasion, and moisture, ensuring smooth operation and extending equipment lifespan.

Aerospace & Defense

Rubber grommets in aerospace provide insulation and protection, preventing corrosion and short circuits, ensuring system reliability in extreme conditions.

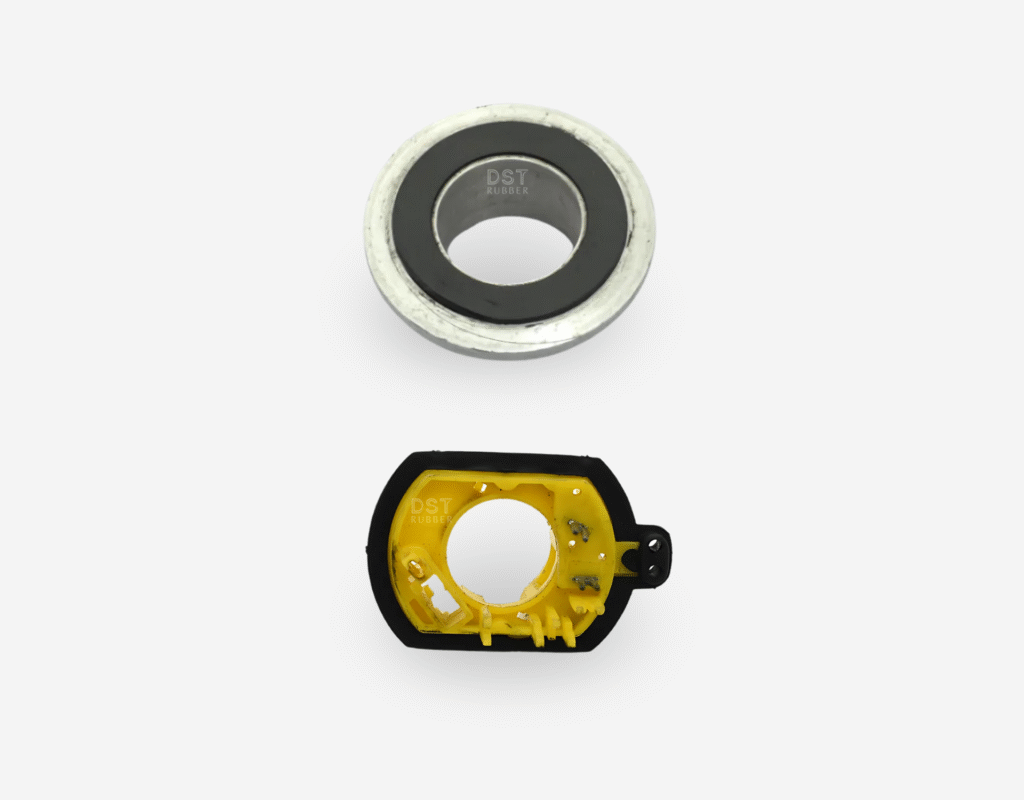

Our Range of Rubber Grommets

At DS Techno Rubber, we specialize in manufacturing a wide range of rubber grommets designed to meet the unique needs of various industries.

Protective Grommets

Shield wires, cables, and tubes from sharp edges, reducing wear and tear. Examples include open grommets and strain relief grommets.

Sealing Grommets

Provide airtight/watertight seals, preventing dust, moisture, and contaminants from entering sensitive areas. Includes blind grommets and multi-hole grommets.

Vibration-Damping Grommets

Reduce noise and vibration in machinery and automotive systems, protecting components from excessive mechanical stress and ensuring smooth operation.

Factors Impacting Rubber Grommet's Durability

Rubber grommets play a crucial role in protecting and insulating wires, cables, and sensitive components. Over time, they may fail due to harsh environments, stress, or extreme temperatures. We address these factors to ensure long-lasting performance.

Material Degradation

Exposure to UV or harsh chemicals can cause cracking, embrittlement, or swelling in rubber.

Compression Set

Prolonged exposure to static loads can cause rubber to lose elasticity, leading to reduced sealing effectiveness.

Abrasion & Mechanical Wear

Continuous contact with moving parts or sharp edges can lead to excessive wear and eventual failure of the rubber.

Thermal Degradation

Excessive heat exposure can cause rubber to harden or melt, impacting its flexibility and overall performance.

Environmental Stress Cracking

Long-term exposure to rain, sunlight, and extreme weather can cause rubber to develop cracks, reducing its strength and flexibility.

Ozone Degradation

Exposure to ozone can cause rubber to deteriorate, leading to cracks and loss of elasticity, affecting its sealing capabilities.

Technical Importance of Rubber Grommets

Rubber grommets are essential for protecting and insulating wires, cables, and components, ensuring reliable sealing, vibration damping, and long-lasting durability, while enhancing overall system performance in a variety of applications.

UV & Ozone Resistance

Our grommets use materials resistant to UV exposure and ozone degradation, ensuring long-term flexibility and integrity.

Compression Resistance

Designed to withstand static loads, maintaining elasticity and seal effectiveness even under prolonged pressure.

Abrasion-Resistant Materials

Engineered with abrasion-resistant compounds, our grommets ensure durability in high-friction environments, reducing wear and tear.

High-Temperature Performance

Heat-resistant materials are selected, allowing grommets to maintain flexibility and strength even at elevated temperatures.

Vibration Absorption

Our grommets reduce vibrations effectively, absorbing shocks to prevent mechanical stress and ensure stable system operation.

Environmental Durability

Built to endure weather exposure and harsh environmental conditions, providing reliable protection in all climates.

Proud Partnerships with Industry Leaders

Custom Rubber Grommets for Your Exhaust Systems

FAQ

Rubber grommets protect cables and wires by securing them in place and preventing abrasion against sharp edges of holes in metal, plastic, or other materials. When a wire or cable passes through a hole, the grommet acts as a cushion, reducing friction and preventing damage to the wire’s insulation. The rubber also provides vibration damping and can help to seal the hole from dust, moisture, or other contaminants, ensuring the safety and longevity of the wiring.

Rubber grommets offer several key benefits, including:

- Protection from abrasion, preventing wires or cables from being damaged by sharp edges in holes

- Vibration damping, reducing the effects of movement or shock on sensitive components

- Sealing capabilities, preventing the entry of dirt, moisture, and dust into holes or connections

- Electrical insulation, helping to protect against short circuits and improve safety

- Flexibility and durability, providing long-lasting performance in demanding environments

Rubber grommets are commonly used in a variety of industries and applications, such as:

- Automotive: To protect wires and cables from sharp metal edges in vehicle bodies and engines

- Electrical and electronics: To insulate wires and cables where they pass through panels or enclosures

- Industrial machinery: To prevent friction and wear in mechanical components or to seal openings in equipment

- Construction and home applications: For sealing holes in doors, windows, and furniture

- Marine and aerospace industries: For sealing cables and wires exposed to moisture and harsh conditions

When selecting a rubber grommet, consider the following factors:

- Hole size and shape to ensure the grommet fits properly

- Material type based on the application’s environment (e.g., EPDM for weather resistance, silicone for high-temperature resistance)

- Thickness and durability of the grommet, depending on the level of protection required

- Temperature and chemical resistance based on the conditions the grommet will be exposed to (e.g., high heat, oils, or solvents)

- Electrical insulation needs, if the grommet will be used in electrical applications

Rubber grommets are typically made from a variety of elastomeric materials, such as:

- Natural Rubber (NR): Provides excellent elasticity and resilience for general-purpose applications

- EPDM (Ethylene Propylene Diene Monomer): Known for weather resistance, ozone resistance, and high-temperature performance

- Silicone: Ideal for high-temperature applications, as it can withstand extreme heat without degrading

- Neoprene (CR): Offers oil, weather, and chemical resistance, making it ideal for industrial use

- Nitrile (NBR): Best for applications involving oil, fuel, and solvents

The choice of material depends on the environmental factors and specific needs of the application.

Get a Custom Quote

Looking for high-quality custom rubber components? We’re here to provide you with tailored solutions that meet your exact requirements. Simply fill out the form below, and we’ll provide a personalized quote based on your specifications.