Rubber Hangers

Custom Rubber Hangers for Automotive and Industrial Applications

At DS Techno Rubber, we specialize in manufacturing durable and high-performance rubber hangers designed to secure and align exhaust systems in a variety of vehicles. Our hangers are engineered to provide superior vibration damping, noise control, and long-lasting durability. Whether for commercial vehicles, passenger cars, or marine systems, our rubber hangers are built to meet the toughest standards for performance and reliability.

Superior Temperature Resistance

Enhanced Flexibility and Durability

Noise and Vibration Control

What are Rubber Hangers?

Rubber hangers are vital components in vehicle exhaust systems, designed to support and secure the exhaust pipe to the vehicle’s metal body. These hangers are primarily used for vibration damping, noise control, and exhaust system alignment, ensuring smooth operation and longevity. Rubber hangers are made from high-quality elastomers that provide flexibility and durability, allowing for slight movement of the exhaust system to prevent stress fractures or damage caused by engine vibrations or road bumps. This flexibility also prevents the exhaust pipe from coming into contact with the ground or the vehicle’s undercarriage, reducing the risk of damage.

They are available in different types to meet specific requirements, including those near the engine, which need to handle higher temperatures and stiffer properties, and those near the exhaust tip, which offer greater flexibility while exposed to lower temperatures.

Automotive Exhaust Systems

Marine Exhaust Systems

Public Transport Systems

Industrial Machinery and Equipment

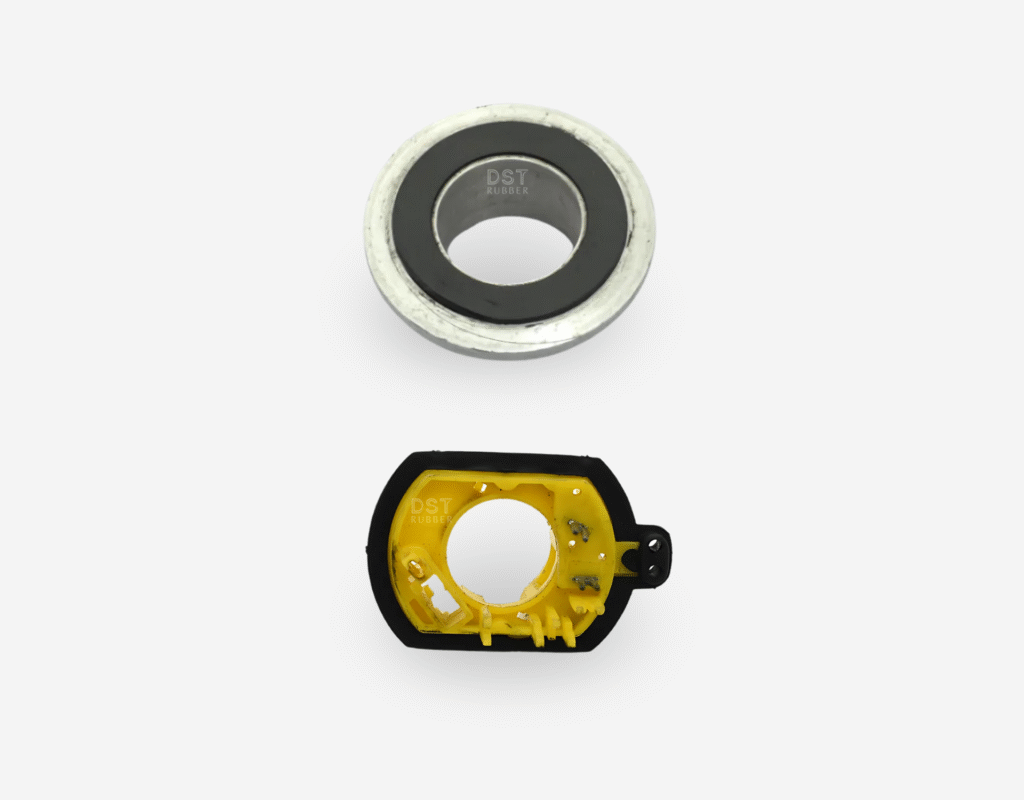

Our Range of Rubber Hangars

At DS Techno Rubber, we specialize in manufacturing a wide range of rubber hangers designed to meet the unique needs of various industries.

Our product range includes hangers for various applications, such as:

Engine-Specific Hangers

Designed to withstand higher temperatures near the engine while offering the necessary stiffness for exhaust system stability

Exhaust Tip Hangers

Offering greater flexibility while exposed to lower temperatures, ensuring optimal performance and no sagging over time.

What Sets Us Apart

OEM and Custom Designs

IATF 16949 Certified

As a company, we are IATF 16949 certified, which ensures that we meet the highest automotive industry standards for quality management.

SQ Mark Certified by Hyundai

We are proud to be SQ Mark certified by Hyundai, signifying our dedication to delivering high-quality products that meet the standards set by global automotive leaders.

Extensive Industry Experience

With years of experience in the rubber industry, we have worked with top OEMs, including Tata and Hyundai, to deliver products that meet the toughest specifications.

Passing Functional Life Tests

Our rubber hangers have successfully passed functional life tests, including those designed for high-performance and extreme conditions, ensuring long-lasting reliability.

Premium Materials

We use premium-grade elastomers for our rubber hangers, ensuring long-lasting durability, flexibility, and high-performance capabilities under varying environmental conditions.

Technical Importance of Rubber Hangers

High Temperature Resistance

Flexibility & Movement Absorption

Vibration Dampening

The primary function of rubber hangers is to dampen vibrations from the engine and road, reducing noise and enhancing the comfort of driving while protecting other components from excessive wear.

Resilience to Weather Conditions

Rubber hangers are exposed to various environmental factors, including rain, sun, and harsh weather. Their resilience ensures that they retain flexibility and strength despite continuous exposure to these elements.

Prevention of Metal-to-Metal Contact

Long-Term Durability

Custom Rubber Hangers for Your Exhaust Systems

FAQ

Rubber hangers act as shock absorbers, isolating vibrations and preventing metal-to-metal contact in exhaust systems, machinery, and piping applications. This reduces noise, structural stress, and excessive movement, making them ideal for automotive, HVAC, and industrial use.

Rubber hangers offer several advantages, including:

- Vibration and noise reduction, improving comfort and equipment longevity

- Heat and weather resistance, ensuring durability in outdoor or high-temperature environments

- Flexibility and shock absorption, preventing damage from sudden movements

- Easy installation and cost-effectiveness compared to metal alternatives

When selecting a rubber hanger, consider the following factors:

- Load capacity – Ensure it can support the required weight

- Operating environment – Check for heat, chemical, or weather exposure

- Mounting style – Choose between loop, bracket, or grommet-style hangers

- Vibration and noise isolation requirements – Select a material with the appropriate damping

properties

Get a Custom Quote

Looking for high-quality custom rubber components? We’re here to provide you with tailored solutions that meet your exact requirements. Simply fill out the form below, and we’ll provide a personalized quote based on your specifications.