Rubber-Metal Bonded Parts

Reliable Rubber-Metal Bonded Parts for Critical Industrial Systems

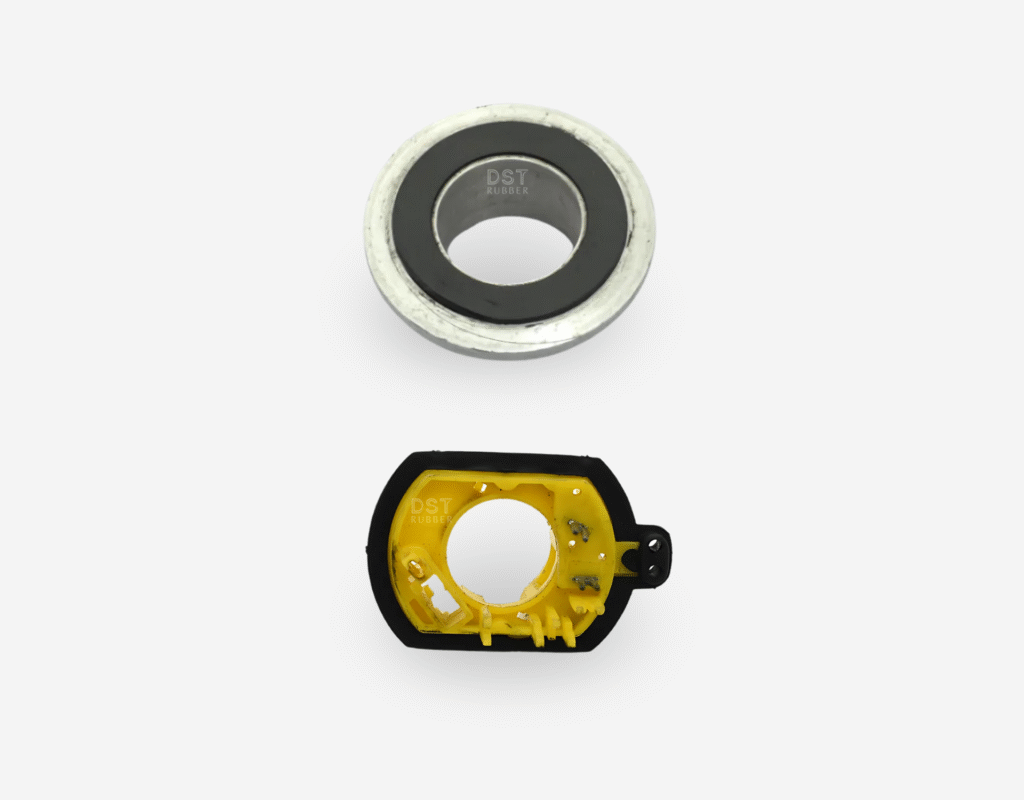

At DS Techno Rubber, we offer a wide range of rubber-metal bonded parts designed to meet the diverse needs of various industries. These parts combine the flexibility and strength of rubber with the durability of metals to provide reliable solutions for vibration isolation, sealing, and structural support. Our rubber-metal bonded components are ideal for use in high-stress environments, offering exceptional performance in automotive, industrial, and commercial applications.

Engineered to withstand high operational loads

Enhanced Vibration Damping

Superior Bond Strength

What are Rubber-Metal Bonded Parts?

Rubber-Metal bonded parts are components made by bonding rubber to metal surfaces, combining the durability and strength of metal with the flexibility and damping properties of rubber. These parts are designed to perform in demanding environments, offering solutions for vibration isolation, noise reduction, sealing, and structural support. The rubber provides flexibility, reducing stress and impact, while the metal ensures strength and stability. The bond between the two materials must be robust and resistant to peeling, shearing, and delamination during the part’s service life, ensuring reliability and long-term performance.

DS Techno Rubber offers high-quality rubber-metal bonded components, designed to meet precise engineering requirements for a variety of industries. Our products undergo rigorous testing to ensure they withstand high operational loads, extreme temperatures, and cyclic stress without failure.

Application Areas of Rubber-Metal Bonded Parts

Vibration Isolation & Damping

Sealing & Fluid Control

Essential in oil seals, gaskets, and valves, rubber-metal bonded parts prevent leakage and ensure airtight and watertight sealing in rotating shafts and other moving components.

Structural Support

Used in piping systems and machinery, rubber-metal bonded parts reduce vibration transmission, absorb shocks, and allow for thermal expansion, ensuring secure and stable structural support.

Shock Absorption in Machinery

Our Range of Rubber-Metal Bonded Parts

We offer a wide variety of rubber-metal bonded parts designed to meet the specific needs of various industries.

Our rubber-metal bonded parts are designed for optimal performance in both automotive and industrial applications, where precision and durability are paramount. Whether you’re looking for vibration-damping components, fluid control parts, or structural support solutions, we have the expertise and product range to meet your needs.

Vibration Isolation & Damping Components

Sealing & Fluid Control Components

We offer rubber-metal bonded parts that prevent leakage in rotating shafts, provide airtight and watertight sealing in automotive and industrial applications, and regulate fluid in pumps and control valves.

Structural Support Components

What Sets Us Apart

At DS Techno Rubber, we provide high-performance rubber-metal bonded parts backed by exceptional testing and manufacturing capabilities. Here’s why you should choose us for your rubber-metal bonding needs:

Comprehensive In-House Testing

Custom Compound Formulation

Robust Vibration Damping

Precise Testing Fixtures

Optimal Fluid Flow for Pumps

Long Shelf Life & Durability

Technical Importance of Rubber-Metal Bonded Parts

Rubber-Metal bonded parts are essential for various industrial applications, combining the flexibility of rubber with the strength of metal to provide high-performance solutions. Their technical properties ensure that they perform reliably under demanding conditions, offering benefits such as vibration isolation, sealing, and structural support.

Robust Bonding

Optimal Compatibility

Performance Under Extreme Conditions

These parts are designed to endure high temperatures and cyclic stresses, ensuring consistent performance and reliability in extreme environments.

Vibration Isolation & Damping

Rubber-Metal bonded parts absorb vibrations and reduce noise, providing smoother operation and improving comfort and equipment lifespan in engines and machinery.

Durability & Longevity

Precision Engineering

Get Custom Rubber-Metal Bonded Parts Tailored to Your Needs

FAQ

Rubber-Metal bonded parts are used in a variety of industries for applications such as vibration isolation

in automotive engines, shock absorption in machinery, sealing in fluid systems, and noise reduction in

industrial equipment. They are ideal for environments that require strength, flexibility, and durability,

such as automotive, aerospace, industrial machinery, and construction.

Rubber-Metal bonded parts offer several key benefits:

- High durability and resistance to wear

- Excellent vibration and noise reduction

- Enhanced sealing capabilities in demanding environments

- Resistance to chemicals, oils, and extreme temperatures

- Customizable designs to fit specific applications

Common materials include:

Rubber: Nitrile (NBR), EPDM, Neoprene, Silicone, and Fluorocarbon (FKM/Viton®), selected based on environmental and chemical resistance needs

Metal: Steel, Aluminum, Brass, and Stainless Steel, chosen for strength, corrosion resistance, and load-bearing capacity

These parts are made through a specialized vulcanization process, where rubber is chemically bonded to

metal using adhesives and heat. This process ensures a strong, permanent bond that can withstand

extreme conditions and mechanical stress.

When choosing a rubber-metal bonded component, consider:

- Load-bearing requirements and expected stress levels

- Environmental conditions (temperature, moisture, chemicals)

- Rubber and metal material compatibility

- Design specifications (shape, size, flexibility needs)

- Industry standards and certifications for specialized applications

Get a Custom Quote

Looking for high-quality custom rubber components? We’re here to provide you with tailored solutions that meet your exact requirements. Simply fill out the form below, and we’ll provide a personalized quote based on your specifications.