Wire Seals

Precision Rubber Wire Seals for Secure Electrical Protection

We manufacture high-performance wire seals designed to protect electrical systems from moisture, dust, chemicals, and environmental damage while allowing reliable wire movement across various industries.

Seals wires in housings, bulkheads, and connectors

Performs in automotive, marine, and telecom systems

Tested for hydraulic fluid, fuel, and solvent resistance

What Are Wire Seals?

Wire seals are precision-moulded rubber components that provide an environmental barrier around wires and cables as they pass through enclosures, housings, or connectors. They are essential for maintaining system integrity in demanding operating conditions.

Automotive

Industry

Seal electrical connectors in wiring harnesses, ECUs, headlamps, and ABS sensors to prevent failure due to water or vibration.

Telecommunication Devices

Protect antenna feeds, tower connectors, and outdoor enclosures. Poor sealing may result in moisture damage, signal interference, or service disruptions.

Marine

Applications

Seal navigation systems, lighting cables, and electrical housings. Exposure without proper sealing can cause corrosion, short circuits, or system breakdowns.

Industrial

Machinery

Used in control panels, automation units, and junction boxes. Faulty seals can lead to dust ingress, equipment failure, or unplanned downtime in critical operations.

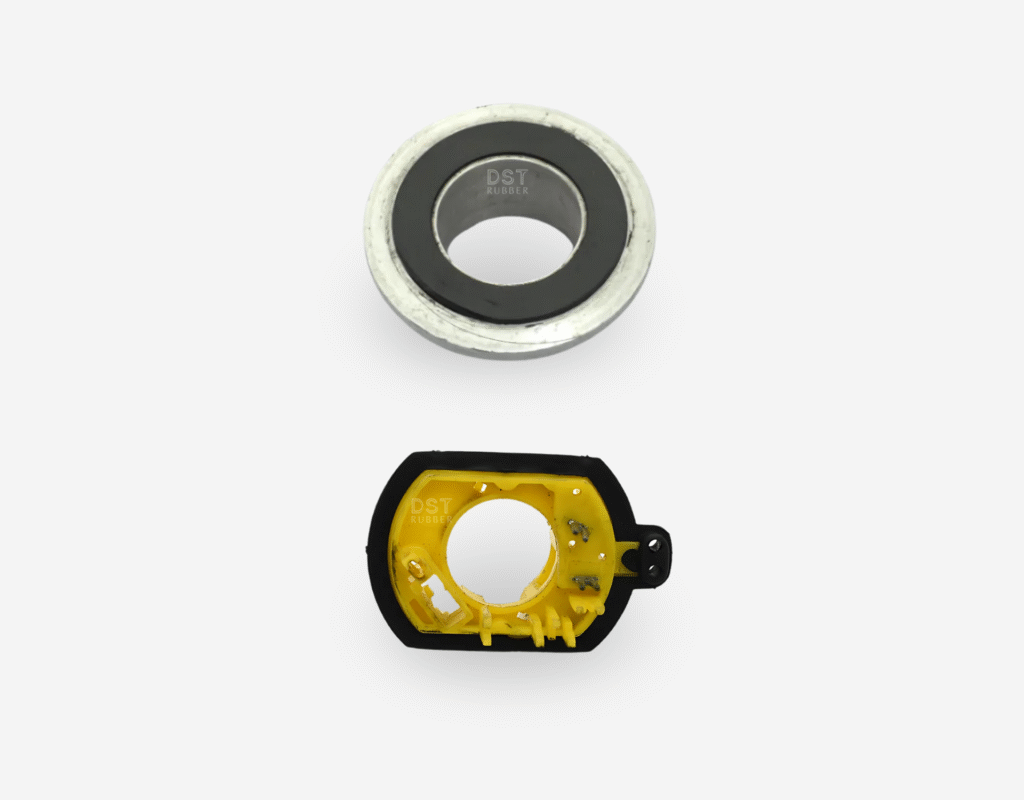

Our Products

We offer a wide range of rubber wire seals built to meet the sealing, durability, and flexibility needs of industrial and high-performance electrical systems.

Connector Interface

Seals

Built to provide environmental sealing and strain relief in standard connector assemblies used across industries.

Pass-Through

Seals

Tailor-made seals to fit unique connector sizes, cable diameters, or IP-rating requirements in advanced systems.

Wire End

Seals

Engineered to withstand continuous exposure to heat, vibration, and chemical exposure in extreme applications.

Common Wire Seals Failures

A failed wire seal allows moisture, dust, or chemicals to enter electrical systems. This can cause short circuits, signal loss, insulation damage, or complete failure in vehicles, industrial machinery, marine equipment, and telecommunication infrastructure.

Seal Cracking

Caused by UV, aging, or wrong material; results in water ingress and loss of sealing.

Improper Sealing Fit

Occurs when wire and hole size mismatch; leads to leakage and vibration-related wear.

Bond Failure or Displacement

Due to poor moulding or movement during assembly; exposes wire and breaks sealing.

Compression Set

Over-compression flattens the seal; reduces grip and long-term sealing effectiveness.

Chemical Degradation

Exposure to oil or solvents; causes swelling, cracks, or material hardening.

Thermal Degradation

Caused by heat cycles; results in brittleness and poor sealing elasticity.

Why Choose DS Techno Rubber Wire Seals?

Engineered with Design Precision

We use tight-tolerance moulds and carefully selected rubber compounds to ensure reliable sealing and dimensional consistency.

Efficient Flash Control

Flash removal is managed through optimized trimming methods that maintain seal integrity and reduce assembly issues.

Precision Moulding Process

Every seal is manufactured using controlled moulding cycles to achieve consistent shape, fit, and performance.

Tested for Lifecycle Durability

Our seals undergo chemical resistance, thermal aging, and pull-out force testing to predict performance and ensure long-term reliability.

Features of Our Wire Seals

Superior Environmental Protection

Shields against moisture, oil, dust, & corrosive elements that commonly degrade electrical systems.

Strain and Vibration Relief

Absorbs mechanical stress to prevent wire damage, connector loosening, and insulation failure.

High Sealing

Integrity

Maintains consistent sealing performance under compression, bending, or thermal stress.

Reliable Under

Stress

Retains sealing, flexibility, and grip under load, wire movement, and temperature changes.

Proud Partnerships with Industry Leaders

Custom Rubber Wire Seals for your Needs

Get in touch today to discuss custom Wire seals tailored to your precise needs!

Industries We Serve

Automotive

Instrumentation and Sensors

Industrial and OEM Applications

Renewable Energy (Windmills)

Hydraulic and Pneumatic Systems

Why DS Techno Rubber?

35+ Years of Expertise

We bring decades of experience in designing and manufacturing custom rubber components.

Precision Engineering

Each diaphragm is crafted with the highest level of attention to detail.

Superior Materials

We use only the finest rubber compounds to ensure durability and performance.

Global Reach

Serving industries in India, the USA, and Germany with high-quality products and on-time delivery.

Frequently Asked Questions (FAQ) about Wire Seals

- Wire seals are used to prevent moisture, dust, oil, and contaminants from entering electrical connectors, housings, or bulkheads.

- They maintain insulation integrity, protect against mechanical strain, and ensure reliable performance in wiring harnesses and sensitive circuits, especially in automotive and industrial systems.

Premium wire seals are made from elastomers like EPDM, NBR (Nitrile), Silicone, and FKM (Viton®). These materials offer excellent resistance to heat, oil, and aging. Manufacturers in India, like DS Techno Rubber, choose compounds based on specific environmental and performance demands of the application.

Rubber wire seals are widely used in the automotive, marine, industrial machinery, and telecommunication sectors. These industries require dependable sealing in connectors exposed to vibration, temperature fluctuations, and harsh environments to prevent electrical failure or data loss.

- To choose the right seal, consider the wire diameter, connector size, required IP rating, environmental exposure, and operating temperature.

- For custom wire sealing solutions in India, working with experienced manufacturers like DST Rubber ensures performance, durability, and perfect fit.

A failed wire seal can cause signal dropouts, corrosion, short circuits, or complete electrical system failure. This is especially critical in vehicles, machinery, and marine equipment. Using tested, high-quality rubber wire seals prevents these issues and increases system reliability and lifespan.

Get a Custom Quote

Looking for high-quality custom rubber components? We’re here to provide you with tailored solutions that meet your exact requirements. Simply fill out the form below, and we’ll provide a personalized quote based on your specifications.